Brioni, the go-to couturier for the likes of Donald Trump, Britain’s Prince Andrew and former South African president Nelson Mandela, has soldiered on through the global recession doing what it does best, producing hand-sewn bespoke suits for men.

Gaetano Savini, who co-founded the company with Nazareno Fonticoli in 1945, instilled “tenacity, and the vision that you have to dare to go beyond the rules of the game,” his grandson Andrea Perrone said.

Perrone, who became Brioni’s chief executive last year, said Savini was the first to stage a fashion show for menswear — in Florence in 1952 — and that Brioni was among the first to create fragrances for men.

PHOTO: AFP

“What I have maybe added is the idea of growing, with emerging markets like China, and to go beyond formal styles, the suit and tie,” Perrone said.

“With the crisis and customers who asked us for discounts or to pay in installments, we launched new categories of products with new fabrics,” he added, recalling an about-face from late 2008, “when the market was demanding more expensive, more luxurious garments.”

At first sight, the group’s main atelier in Penne di Pescara, on Italy’s Adriatic Coast, looks like a factory, but without machines.

Some 1,100 technicians and seamstresses ply their trade, designing patterns, cutting cloth with enormous scissors, sewing on a sleeve here, finishing a buttonhole there, or a hem ... then pressing carefully and checking their work.

“It takes us 18 to 22 hours to make a man’s suit, sometimes up to 48 hours,” chief master tailor Angelo Petrucci, 39, said.

By comparison, mass-produced suits take two to three hours to complete.

Each Brioni suitcoat counts between 5,000 and 7,000 stitches and is handled an average of 220 times — including 80 pressings.

“Even though we work by hand, we have specific time standards. For example, 15 minutes to insert a shoulder pad,” said Clementina Litillo, who at 57 is about to retire after 40 years.

The work is more complicated than a decade ago, Petrucci said, because clients are always after softer and finer fabrics.

Pointing out a lining consisting of camel, goat and horse hair, he said each creation has a “soul.”

Holding up a huge jacket created for a Japanese client, a former sumo wrestler, Petrucci said: “We can make obese people look thinner, short people look taller. We can even correct for bone defects by inserting all kinds of prostheses.”

Over the years, Brioni has built up a database to keep track of its clients around the world, many from the Middle East and Asia.

To be a good tailor, “you have to have sensitive hands, so you have to start very, very young,” Petrucci said. “After age 20, you can’t learn it.”

Petrucci himself started at age 13, when he began a four-year apprenticeship at Brioni.

The breeding ground of skill and talent shared among the technicians and seamstresses has been the secret of Brioni’s success, allowing it to survive a wave of retirements in the early 1990s just as sales were skyrocketing.

The global recession has not led to smaller price tags at the family firm, even though its annual turnover of about 200 million euros (US$265 million) shrank by 15 percent last year — 20 percent in the US.

A custom-made suit may cost up to 6,000 euros, while a fully personalized ensemble could cost as much as 30,000 euros.

“It’s not an expensive product, but a costly one, reflecting the hours and hours of work, but it can last more than 40 years,” Petrucci said.

In recent years, the group has diversified its range, offering lines for women and casual clothes, such as jeans and polo shirts, now nearly 40 percent of its sales.

The downside?

Sometimes Petrucci’s Blackberry will wake him in the middle of the night with an e-mail from a faraway client needing an emergency alteration.

Asked to describe the Brioni tailor of today, Perrone said: “When you think of a tailor, you think of a balding old man with little glasses leaning over his work. At Brioni, we have real managers, who travel, use new technologies, they’re tailors with Blackberries.”

Brioni has 65 stores around the world, with some new openings planned in the coming years.

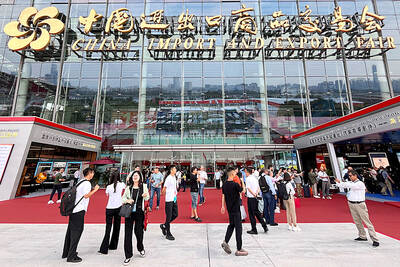

The priority is China, “where we just opened a new store in Shanghai ahead of the Expo there, having opened a first store in Beijing a year ago,” Perrone said.

One thing Brioni does not worry about, whatever the state of the world economy, is advertising.

“Our best advertising is by word of mouth,” Perrone said. “Unlike other labels that try to make a new selling point out of an artisanal tradition, we don’t need to because it’s in our DNA.”

SECURITY: As China is ‘reshaping’ Hong Kong’s population, Taiwan must raise the eligibility threshold for applications from Hong Kongers, Chiu Chui-cheng said When Hong Kong and Macau citizens apply for residency in Taiwan, it would be under a new category that includes a “national security observation period,” Mainland Affairs Council (MAC) Minister Chiu Chui-cheng (邱垂正) said yesterday. President William Lai (賴清德) on March 13 announced 17 strategies to counter China’s aggression toward Taiwan, including incorporating national security considerations into the review process for residency applications from Hong Kong and Macau citizens. The situation in Hong Kong is constantly changing, Chiu said to media yesterday on the sidelines of the Taipei Technology Run hosted by the Taipei Neihu Technology Park Development Association. With

CARROT AND STICK: While unrelenting in its military threats, China attracted nearly 40,000 Taiwanese to over 400 business events last year Nearly 40,000 Taiwanese last year joined industry events in China, such as conferences and trade fairs, supported by the Chinese government, a study showed yesterday, as Beijing ramps up a charm offensive toward Taipei alongside military pressure. China has long taken a carrot-and-stick approach to Taiwan, threatening it with the prospect of military action while reaching out to those it believes are amenable to Beijing’s point of view. Taiwanese security officials are wary of what they see as Beijing’s influence campaigns to sway public opinion after Taipei and Beijing gradually resumed travel links halted by the COVID-19 pandemic, but the scale of

A US Marine Corps regiment equipped with Naval Strike Missiles (NSM) is set to participate in the upcoming Balikatan 25 exercise in the Luzon Strait, marking the system’s first-ever deployment in the Philippines. US and Philippine officials have separately confirmed that the Navy Marine Expeditionary Ship Interdiction System (NMESIS) — the mobile launch platform for the Naval Strike Missile — would take part in the joint exercise. The missiles are being deployed to “a strategic first island chain chokepoint” in the waters between Taiwan proper and the Philippines, US-based Naval News reported. “The Luzon Strait and Bashi Channel represent a critical access

Pope Francis is be laid to rest on Saturday after lying in state for three days in St Peter’s Basilica, where the faithful are expected to flock to pay their respects to history’s first Latin American pontiff. The cardinals met yesterday in the Vatican’s synod hall to chart the next steps before a conclave begins to choose Francis’ successor, as condolences poured in from around the world. According to current norms, the conclave must begin between May 5 and 10. The cardinals set the funeral for Saturday at 10am in St Peter’s Square, to be celebrated by the dean of the College