Foxconn Technology Group (富士康科技集團) yesterday said it expects any impact of new tariffs from US president-elect Donald Trump to hit the company less than its rivals, citing its global manufacturing footprint.

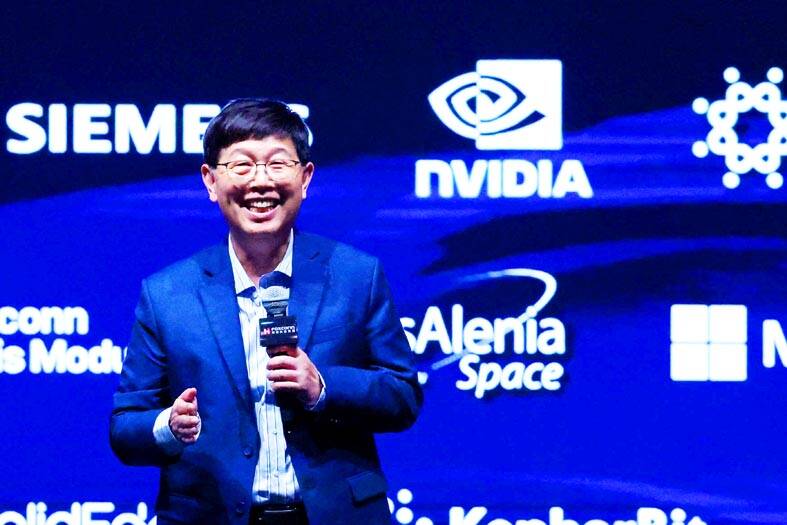

Young Liu (劉揚偉), chairman of the contract manufacturer and key Apple Inc supplier, told reporters after a forum in Taipei that it saw the primary impact of any fresh tariffs falling on its clients because its business model is based on contract manufacturing.

“Clients may decide to shift production locations, but looking at Foxconn’s global footprint, we are ahead. As a result, the impact on us is likely smaller compared to our competitors,” he said.

Photo: Reuters

Trump on Monday said that on his first day in office he would impose a 25 percent tariff on all products from Mexico and Canada and would charge goods from China an additional 10 percent tariff.

Foxconn, the world’s largest contract electronics maker, has large facilities in China, including a giant iPhone assembly plant.

However, it has been increasing its investments in other countries, such as the US, Mexico and Vietnam, as part of a supply chain diversification effort. In Mexico, it is building a large manufacturing facility to produce Nvidia Corp’s GB200 superchips.

Liu said Foxconn would only be able to share more details about the company’s US plans after Jan. 20, once Trump takes office and his policies become clearer.

“After that, we will have a corresponding strategy in place,” he said.

“What you’re seeing now is a game between nations, not yet between companies. Whether it’s 25 percent or an additional 10 percent, the outcome is uncertain as they continue to negotiate. We are constantly adapting and refining our global strategy,” Liu said.

During Trump’s previous presidency from 2017 to 2021, Foxconn announced a US$10 billion investment in Wisconsin that the company later mostly abandoned. On Tuesday, Foxconn said a subsidiary had spent US$33 million to acquire land and factory buildings in Harris County, Texas.

Foxconn will continue investing in Mexico, Liu added, as it believed the trend was moving toward regional manufacturing.

Hon Hai Precision Industry Co (鴻海精密), the flagship firm of the group, has invested US$33.03 million to buy land and a building in Texas that sources say would be used to expand the company’s artificial intelligence server production in the US.

In a statement posted on the Taiwan Stock Exchange (TWSE), where Taiwan-based Hon Hai’s shares are traded, the company on Tuesday said that subsidiary Foxconn Assembly LLC has acquired 478,036m2 of land and a building with an area of 200,200m2 in Harris County.

At an investors’ conference last month, Liu said his company would continue to invest in artificial intelligence products and electric vehicles in the US market.

According to Liu, Hon Hai has invested in the US for almost four decades and now operates 50 facilities there with a workforce of about 5,000 people that generate US$25.6 billion in annual sales.

Additional reporting by CNA

‘SWASTICAR’: Tesla CEO Elon Musk’s close association with Donald Trump has prompted opponents to brand him a ‘Nazi’ and resulted in a dramatic drop in sales Demonstrators descended on Tesla Inc dealerships across the US, and in Europe and Canada on Saturday to protest company chief Elon Musk, who has amassed extraordinary power as a top adviser to US President Donald Trump. Waving signs with messages such as “Musk is stealing our money” and “Reclaim our country,” the protests largely took place peacefully following fiery episodes of vandalism on Tesla vehicles, dealerships and other facilities in recent weeks that US officials have denounced as terrorism. Hundreds rallied on Saturday outside the Tesla dealership in Manhattan. Some blasted Musk, the world’s richest man, while others demanded the shuttering of his

TIGHT-LIPPED: UMC said it had no merger plans at the moment, after Nikkei Asia reported that the firm and GlobalFoundries were considering restarting merger talks United Microelectronics Corp (UMC, 聯電), the world’s No. 4 contract chipmaker, yesterday launched a new US$5 billion 12-inch chip factory in Singapore as part of its latest effort to diversify its manufacturing footprint amid growing geopolitical risks. The new factory, adjacent to UMC’s existing Singapore fab in the Pasir Res Wafer Fab Park, is scheduled to enter volume production next year, utilizing mature 22-nanometer and 28-nanometer process technologies, UMC said in a statement. The company plans to invest US$5 billion during the first phase of the new fab, which would have an installed capacity of 30,000 12-inch wafers per month, it said. The

MULTIFACETED: A task force has analyzed possible scenarios and created responses to assist domestic industries in dealing with US tariffs, the economics minister said The Executive Yuan is tomorrow to announce countermeasures to US President Donald Trump’s planned reciprocal tariffs, although the details of the plan would not be made public until Monday next week, Minister of Economic Affairs J.W. Kuo (郭智輝) said yesterday. The Cabinet established an economic and trade task force in November last year to deal with US trade and tariff related issues, Kuo told reporters outside the legislature in Taipei. The task force has been analyzing and evaluating all kinds of scenarios to identify suitable responses and determine how best to assist domestic industries in managing the effects of Trump’s tariffs, he

Taiwan’s official purchasing managers’ index (PMI) last month rose 0.2 percentage points to 54.2, in a second consecutive month of expansion, thanks to front-loading demand intended to avoid potential US tariff hikes, the Chung-Hua Institution for Economic Research (CIER, 中華經濟研究院) said yesterday. While short-term demand appeared robust, uncertainties rose due to US President Donald Trump’s unpredictable trade policy, CIER president Lien Hsien-ming (連賢明) told a news conference in Taipei. Taiwan’s economy this year would be characterized by high-level fluctuations and the volatility would be wilder than most expect, Lien said Demand for electronics, particularly semiconductors, continues to benefit from US technology giants’ effort