GlobalWafers Corp (環球晶圓), the world’s third-largest silicon wafer supplier, yesterday reported that net profit last quarter rose 2.6 percent from a quarter earlier and growth momentum would extend into this quarter and next year.

Net profit improved to NT$2.95 billion (US$92.28 million) in the July-to-September period, compared with NT$2.88 billion in the second quarter.

On an annual basis, net profit plummeted 46.7 percent from NT$5.54 billion.

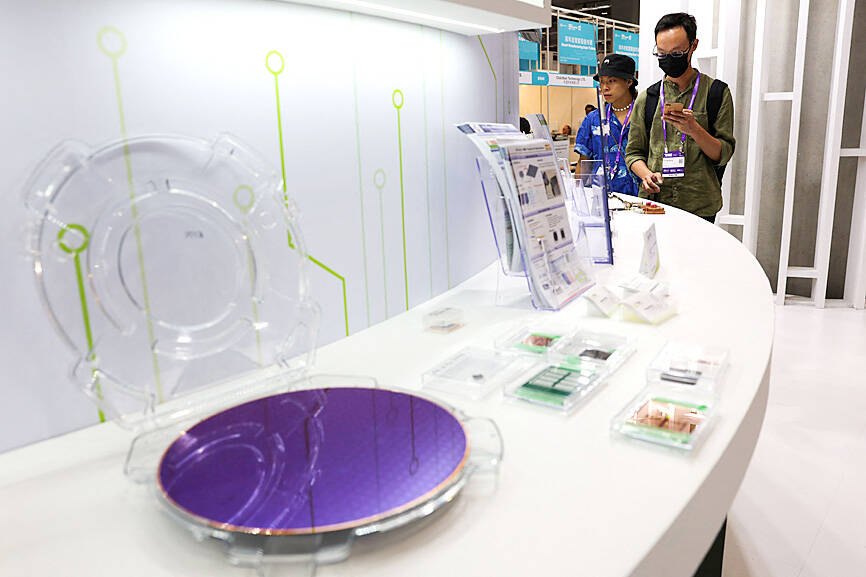

Photo: Ann Wang, Reuters

Earnings per share rose to NT$6.18 last quarter from NT$6.02 in the second quarter, but declined from NT$12.73 in the third quarter last year.

The Hsinchu-based company said the worst has passed, and that revenue would pick up this quarter and next year, despite slower-than-expected inventory adjustments by customers.

Sagging demand for its compound semiconductors was another factor as revenue last quarter contracted 8.7 percent, GlobalWafers said.

“I think that fourth-quarter revenue will be higher than the second quarter and third quarter,” GlobalWafers chairwoman Doris Hsu (徐秀蘭) told investors yesterday.

The company hopes revenue next year would return to last year’s level of NT$70.65 billion, an all-time high, Hsu said.

“As inventory levels normalize at the end of the year, we anticipate a market recovery in 2025 driven by improving demand and capacity expansion by customers,” she said, adding that revenue growth would help alleviate rises in equipment costs and facility depreciation.

With an improving fab utilization rate, gross margin would “bottom out” next year, Hsu said.

Gross margin tumbled to the lowest in seven years at 30 percent last quarter, down from 36.6 percent a year earlier and 32.3 percent in the second quarter.

However, the recovery in customer demand was uneven last quarter, Hsu said.

Demand for advanced technology helped lift the utilization rate at its 12-inch fab to about 90 percent, but equipment loading for mature technology and 8-inch fabs remained low as a result of customers’ high chip inventories and sluggish demand for chips used in industrial devices and vehicles, she said.

GlobalWafers said it would continue supplying 6-inch wafers to customers in the vehicle sector, but it would raise wafer prices to reflect higher manufacturing costs.

In addition to US$400 million in direct funding from the CHIPS Act for its US investments, GlobalWafers said it has obtained a 25 percent tax credit based on the Advanced Manufacturing Investment Credit from the US government.

When an apartment comes up for rent in Germany’s big cities, hundreds of prospective tenants often queue down the street to view it, but the acute shortage of affordable housing is getting scant attention ahead of today’s snap general election. “Housing is one of the main problems for people, but nobody talks about it, nobody takes it seriously,” said Andreas Ibel, president of Build Europe, an association representing housing developers. Migration and the sluggish economy top the list of voters’ concerns, but analysts say housing policy fails to break through as returns on investment take time to register, making the

NOT TO WORRY: Some people are concerned funds might continue moving out of the country, but the central bank said financial account outflows are not unusual in Taiwan Taiwan’s outbound investments hit a new high last year due to investments made by contract chipmaker Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) and other major manufacturers to boost global expansion, the central bank said on Thursday. The net increase in outbound investments last year reached a record US$21.05 billion, while the net increase in outbound investments by Taiwanese residents reached a record US$31.98 billion, central bank data showed. Chen Fei-wen (陳斐紋), deputy director of the central bank’s Department of Economic Research, said the increase was largely due to TSMC’s efforts to expand production in the US and Japan. Investments by Vanguard International

WARNING SHOT: The US president has threatened to impose 25 percent tariffs on all imported vehicles, and similar or higher duties on pharmaceuticals and semiconductors US President Donald Trump on Wednesday suggested that a trade deal with China was “possible” — a key target in the US leader’s tariffs policy. The US in 2020 had already agreed to “a great trade deal with China” and a new deal was “possible,” Trump said. Trump said he expected Chinese President Xi Jinping (習近平) to visit the US, without giving a timeline for his trip. Trump also said that he was talking to China about TikTok, as the US seeks to broker a sale of the popular app owned by Chinese firm ByteDance Ltd (字節跳動). Trump last week said that he had

STRUGGLING TO SURVIVE: The group is proposing a consortium of investors, with Tesla as the largest backer, and possibly a minority investment by Hon Hai Precision Nissan Motor Co shares jumped after the Financial Times reported that a high-level Japanese group has drawn up plans to seek investment from Elon Musk’s Tesla Inc to aid the struggling automaker. The group believes the electric vehicle (EV) maker is interested in acquiring Nissan’s plants in the US, the newspaper reported, citing people it did not identify. The proposal envisions a consortium of investors, with Tesla as the largest backer, but also includes the possibility of a minority investment by Hon Hai Precision Industry Co (鴻海精密) to prevent a full takeover by the Apple supplier, the report said. The group is