The production value of Taiwan’s semiconductor equipment is likely to grow this year after falling 7.3 percent last year amid strong global demand for artificial intelligence (AI) and other emerging technologies, the Ministry of Economic Affairs said.

The ministry made the comment last week after reporting that the production value of Taiwan-made semiconductor equipment for the first five months of this year rose by 5.5 percent from a year earlier to NT$62.7 billion (US$1.93 billion).

If the forecast is correct, the production value of Taiwan’s semiconductor equipment would be higher than the NT$149.7 billion last year and stay above the NT$100 million level for the fifth consecutive year.

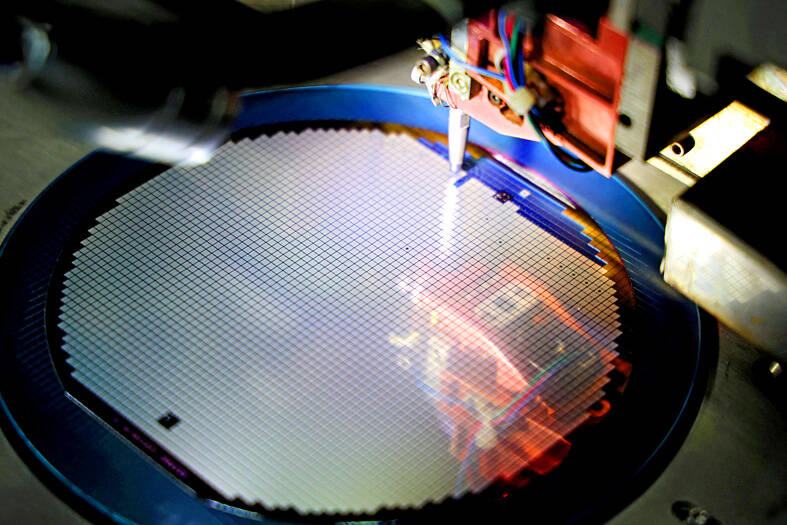

Photo: AFP

As companies accelerated digital transformation and pursued industrial automation following the impact of the COVID-19 pandemic, market demand for semiconductors has been booming in recent years, which has driven semiconductor companies to actively invest in capacity expansion, the ministry said in a statement.

The production value of Taiwan’s semiconductor equipment — composed mainly of manufacturing and inspection equipment, and its related components — surpassed NT$100 billion in 2020, reaching NT$103.1 billion, up 47.3 percent compared with 2019, ministry data showed.

After 2020, production value registered two consecutive years of double-digit percentage growth, but decreased by 7.3 percent annually last year after high inflation and interest rates worldwide, which seriously dented consumer consumption and business investment, the ministry said.

This year, the rise of AI opportunities and strong demand for high-performance computing applications have greatly pushed up the market’s demand for advanced semiconductor processes and boosted the semiconductor equipment sector’s growth momentum from January to May, it said.

Taiwan Semiconductor Manufacturing Co (台積電), the world’s largest contract chipmaker and a market leader in terms of advanced technologies, last month told investors that it would hike its capital expenditure budget for this year to between US$30 billion and US$32 billion, compared with its earlier estimate of US$28 billion to US$32 billion.

The production value of semiconductor manufacturing equipment and components returned to positive growth at 6.9 percent in the first five months, after posting an annual decrease of 5.7 percent last year, accounting for 78.5 percent of the overall sales of semiconductor equipment, the ministry said.

Semiconductor inspection equipment and components contributed 21.5 percent to the sector’s total sales in the five-month period, with production value edging up 0.7 percent from a year earlier, the ministry added.

As Taiwanese semiconductor equipment suppliers intensified efforts to explore business opportunities abroad over the past few years, their exports exceeded 50 percent of total shipments for the first time last year, the ministry said.

Exports of semiconductor equipment reached US$1.48 billion in the first half of this year, an 8.2 percent increase from the same period last year, customs data from the Ministry of Finance showed.

China, including Hong Kong, remained the largest destination for Taiwanese equipment exports, accounting for 35.7 percent of the total in the first six months, while Singapore became the second-largest market with 21.2 percent share of Taiwanese exports as the city-state strongly promoted semiconductor investment there, the data showed.

UNCERTAINTY: Innolux activated a stringent supply chain management mechanism, as it did during the COVID-19 pandemic, to ensure optimal inventory levels for customers Flat-panel display makers AUO Corp (友達) and Innolux Corp (群創) yesterday said that about 12 to 20 percent of their display business is at risk of potential US tariffs and that they would relocate production or shipment destinations to mitigate the levies’ effects. US tariffs would have a direct impact of US$200 million on AUO’s revenue, company chairman Paul Peng (彭雙浪) told reporters on the sidelines of the Touch Taiwan trade show in Taipei yesterday. That would make up about 12 percent of the company’s overall revenue. To cope with the tariff uncertainty, AUO plans to allocate its production to manufacturing facilities in

TAKING STOCK: A Taiwanese cookware firm in Vietnam urged customers to assess inventory or place orders early so shipments can reach the US while tariffs are paused Taiwanese businesses in Vietnam are exploring alternatives after the White House imposed a 46 percent import duty on Vietnamese goods, following US President Donald Trump’s announcement of “reciprocal” tariffs on the US’ trading partners. Lo Shih-liang (羅世良), chairman of Brico Industry Co (裕茂工業), a Taiwanese company that manufactures cast iron cookware and stove components in Vietnam, said that more than 40 percent of his business was tied to the US market, describing the constant US policy shifts as an emotional roller coaster. “I work during the day and stay up all night watching the news. I’ve been following US news until 3am

COLLABORATION: Given Taiwan’s key position in global supply chains, the US firm is discussing strategies with local partners and clients to deal with global uncertainties Advanced Micro Devices Inc (AMD) yesterday said it is meeting with local ecosystem partners, including Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), to discuss strategies, including long-term manufacturing, to navigate uncertainties such as US tariffs, as Taiwan occupies an important position in global supply chains. AMD chief executive officer Lisa Su (蘇姿丰) told reporters that Taiwan is an important part of the chip designer’s ecosystem and she is discussing with partners and customers in Taiwan to forge strong collaborations on different areas during this critical period. AMD has just become the first artificial-intelligence (AI) server chip customer of TSMC to utilize its advanced

Six years ago, LVMH’s billionaire CEO Bernard Arnault and US President Donald Trump cut the blue ribbon on a factory in rural Texas that would make designer handbags for Louis Vuitton, one of the world’s best-known luxury brands. However, since the high-profile opening, the factory has faced a host of problems limiting production, 11 former Louis Vuitton employees said. The site has consistently ranked among the worst-performing for Louis Vuitton globally, “significantly” underperforming other facilities, said three former Louis Vuitton workers and a senior industry source, who cited internal rankings shared with staff. The plant’s problems — which have not