At a factory in Finland, the “farmers of the future” are making a new food protein by feeding a microbe air and electricity, proving that protein can be produced without traditional agriculture.

Livestock farming is one of the main culprits in greenhouse gas emissions, the primary cause of climate change. Cellular agriculture, where food or nutrients are grown from cell cultures, is increasingly seen as a green alternative to animal agriculture.

Lab-grown meat, eggs and milk have made headlines over the past few years, with scientists using animal cell cultures — a process some have criticized as unnatural, highly processed, energy-consuming and costly.

Photo: AFP

However, at Solar Foods’ new factory outside Helsinki, scientists are using new technology to grow protein out of cells using air and electricity.

By feeding a microbe with carbon dioxide, hydrogen and some minerals, and powering the process with electricity from renewable sources, the company has managed to create a protein-rich powder that can be used as a milk and egg substitute.

“We can source our main feedstock for the microbe from the air,” Solar Foods chief executive officer Pasi Vainikka said, as he gave a tour of the company’s new facilities.

Photo: AFP

“We have started the production of the world’s most sustainable protein,” he added.

Founded by Vainikka and Juha-Pekka Pitkanen in 2017, Solar Foods launched the “world’s first factory growing food out of thin air” last month.

“Much of the animal-like protein of today can actually be produced through cellular agriculture and we can let agricultural land rewild and thereby build carbon stock,” Vainikka said, referring to the process whereby forests and soil absorb and store carbon.

Photo: AFP

One kilogram of the new protein, dubbed “solein,” emits 130 times less greenhouse gases than the same amount of protein produced by beef production in the EU, a 2021 scientific study said.

Vainikka navigates his way through the factory’s laboratory and into the control room, where a dozen people at computer screens monitor the production process.

“These are our future farmers,” Vainikka said.

Transforming food production and consumption is at the heart of combating the climate crisis and preventing biodiversity loss, said Emilia Nordlund, head of industrial biotechnology and food research at the VTT Technical Research Centre.

However, current projections show the consumption of meat is expected to increase in coming years.

“Industrial food production, especially livestock production, is one of the biggest causes of greenhouse gas emissions [and] the biggest cause of biodiversity loss, eutrophication and freshwater usage,” she said.

New food production technologies can help cut emissions and “decentralize and diversify food production,” Nordlund said.

“However, at the same time, we must improve the existing food production methods to make them more sustainable and resilient,” she added.

Fermentation technology used to produce nutrients, such as proteins, has been around for decades.

However, the field has expanded significantly over the past few years, with new technological solutions and research projects emerging worldwide.

Some of the most active start-up hubs focusing on cellular agriculture are in the US, the UK, Germany, the Netherlands and Israel, Nordlund said.

“We are in a crucial phase as we will see which start-ups will survive,” she said, adding that stalling bureaucracy was slowing cellular agriculture’s take-off in the EU.

Dressed in protective gear to prevent bacteria contamination in the factory, Vainikka showed off a giant steel tank in a shiny production hall.

“This is a fermenter holding 20,000 liters,” he said, adding that the microbe multiplies inside the tank as it gets fed the greenhouse gas.

Liquid containing the microbes is continuously extracted from the tank to be processed into the yellowish protein-rich powder with a flavor described as “nutty” and “creamy.” “The fermenter produces the same amount of protein per day as 300 milking cows or 50,000 laying hens,” Vainikka said.

That equals “5 million meals worth of protein per year,” he said.

For now, the main purpose of the small Finnish plant employing about 40 people is to “prove that the technology scales,” so it can attract the necessary investments pending European regulatory approval.

While the protein has been cleared for sale in Singapore where some restaurants have used it to make ice cream, it is still awaiting classification as a food product in the EU and the US.

To have any real impact, the aim is to “build an industrial plant 100 times the size of this one,” Vainikka said.

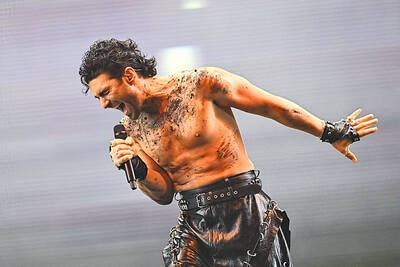

The Eurovision Song Contest has seen a surge in punter interest at the bookmakers, becoming a major betting event, experts said ahead of last night’s giant glamfest in Basel. “Eurovision has quietly become one of the biggest betting events of the year,” said Tomi Huttunen, senior manager of the Online Computer Finland (OCS) betting and casino platform. Betting sites have long been used to gauge which way voters might be leaning ahead of the world’s biggest televised live music event. However, bookmakers highlight a huge increase in engagement in recent years — and this year in particular. “We’ve already passed 2023’s total activity and

BIG BUCKS: Chairman Wei is expected to receive NT$34.12 million on a proposed NT$5 cash dividend plan, while the National Development Fund would get NT$8.27 billion Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the world’s largest contract chipmaker, yesterday announced that its board of directors approved US$15.25 billion in capital appropriations for long-term expansion to meet growing demand. The funds are to be used for installing advanced technology and packaging capacity, expanding mature and specialty technology, and constructing fabs with facility systems, TSMC said in a statement. The board also approved a proposal to distribute a NT$5 cash dividend per share, based on first-quarter earnings per share of NT$13.94, it said. That surpasses the NT$4.50 dividend for the fourth quarter of last year. TSMC has said that while it is eager

‘IMMENSE SWAY’: The top 50 companies, based on market cap, shape everything from technology to consumer trends, advisory firm Visual Capitalist said Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) was ranked the 10th-most valuable company globally this year, market information advisory firm Visual Capitalist said. TSMC sat on a market cap of about US$915 billion as of Monday last week, making it the 10th-most valuable company in the world and No. 1 in Asia, the publisher said in its “50 Most Valuable Companies in the World” list. Visual Capitalist described TSMC as the world’s largest dedicated semiconductor foundry operator that rolls out chips for major tech names such as US consumer electronics brand Apple Inc, and artificial intelligence (AI) chip designers Nvidia Corp and Advanced

Pegatron Corp (和碩), an iPhone assembler for Apple Inc, is to spend NT$5.64 billion (US$186.82 million) to acquire HTC Corp’s (宏達電) factories in Taoyuan and invest NT$578.57 million in its India subsidiary to expand manufacturing capacity, after its board approved the plans on Wednesday. The Taoyuan factories would expand production of consumer electronics, and communication and computing devices, while the India investment would boost production of communications devices and possibly automotive electronics later, a Pegatron official told the Taipei Times by telephone yesterday. Pegatron expects to complete the Taoyuan factory transaction in the third quarter, said the official, who declined to be