Contract chipmaker Powerchip Semiconductor Manufacturing Corp (力積電) yesterday said revenue would gradually pick up in the second half of this year due to restocking demand and an optimized product portfolio in response to growing demand for artificial intelligence (AI) applications.

The Hsinchu-based chipmaker has been adjusting its product portfolios for the past two years with the aim of meeting demand from major customers, who were diversifying from China amid geopolitical risks, Powerchip president Brian Shieh (謝再居) told shareholders during the company’s annual general meeting in Hsinchu yesterday.

Powerchip is also developing a new process technology to make power management chips, vying for business opportunities in the Internet of Things (IoT), AI, high-performance computing and electric vehicle arenas, he said.

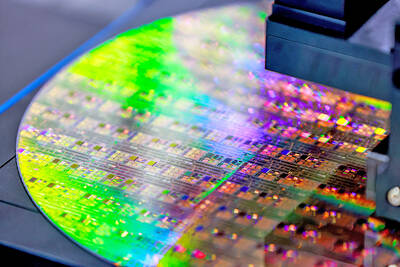

Photo: Grace Hung, Taipei Times

“With all those preparations and product line adjustments, we hope the effect will emerge from the second half to the first half of next year after customers reduce their inventory to normal levels,” Shieh said. “With capacity from the new fab in [Miaoli County’s] Tongluo Township (銅鑼) coming online in the second half, we anticipate the company’s revenue would gradually recover.”

Powerchip’s revenue fell 5.3 percent year-on-year to NT$14.5 billion (US$449 million) in the first four months of this year, following a 42 percent annual decline to NT$44 billion last year due to inventory adjustments.

Through product optimization, Powerchip is also looking to fend off rising competition from Chinese chipmakers, Shieh said.

China’s biggest chipmaker, Semiconductor Manufacturing International Corp (中芯), and Nexchip Semiconductor Corp (晶合) are major rivals to Powerchip.

Chinese companies expanded their capacity last year to produce display ICs, CMOS image sensors and power management chips using mature process technologies, but they had to drastically slash prices to compete for market share, Powerchip said.

Powerchip is also developing advanced “wafer-on-wafer” packaging technology as demand for devices such as PCs and smartphones with generative AI applications increases, Shieh said.

Powerchip plans to expand its product offerings to match customers’ demand for “single-level-cell” NAND and high-density NOR flash memory chips used in networking, mobile phones, IoT and computer peripherals, he said.

The company also plans to produce gallium nitride chips by rejuvenating its less-advanced 8-inch fabs, as well as power semiconductors including metal-oxide-semiconductor field-effect transistors and insulated gate bipolar transistors, he added.

Powerchip shareholders yesterday approved a proposal not to pay a cash dividend after the chipmaker lost NT$1.6 billion, or losses per share of NT$0.4, last year.

The company also booked NT$10.3 billion in idled manufacturing equipment losses and expenditures of NT$2.4 billion for the opening of the new fab in Tongluo Township.

The company last month said that it was approaching the break-even level last quarter as customers have reduced their inventory of chips used in consumer electronics such as smartphones, PCs and TVs to healthy levels.

Automotive and industrial chips were still in the process of inventory digestion, it said.

Taiwan’s rapidly aging population is fueling a sharp increase in homes occupied solely by elderly people, a trend that is reshaping the nation’s housing market and social fabric, real-estate brokers said yesterday. About 850,000 residences were occupied by elderly people in the first quarter, including 655,000 that housed only one resident, the Ministry of the Interior said. The figures have nearly doubled from a decade earlier, Great Home Realty Co (大家房屋) said, as people aged 65 and older now make up 20.8 percent of the population. “The so-called silver tsunami represents more than just a demographic shift — it could fundamentally redefine the

Businesses across the global semiconductor supply chain are bracing themselves for disruptions from an escalating trade war, after China imposed curbs on rare earth mineral exports and the US responded with additional tariffs and restrictions on software sales to the Asian nation. China’s restrictions, the most targeted move yet to limit supplies of rare earth materials, represent the first major attempt by Beijing to exercise long-arm jurisdiction over foreign companies to target the semiconductor industry, threatening to stall the chips powering the artificial intelligence (AI) boom. They prompted US President Donald Trump on Friday to announce that he would impose an additional

China Airlines Ltd (CAL, 中華航空) said it expects peak season effects in the fourth quarter to continue to boost demand for passenger flights and cargo services, after reporting its second-highest-ever September sales on Monday. The carrier said it posted NT$15.88 billion (US$517 million) in consolidated sales last month, trailing only September last year’s NT$16.01 billion. Last month, CAL generated NT$8.77 billion from its passenger flights and NT$5.37 billion from cargo services, it said. In the first nine months of this year, the carrier posted NT$154.93 billion in cumulative sales, up 2.62 percent from a year earlier, marking the second-highest level for the January-September

Asian e-commerce giant Shein’s (希音) decision to set up shop in a historic Parisian department store has ruffled feathers in the fashion capital. Anger has been boiling since Shein announced last week that it would open its first permanent physical store next month at BHV Marais, an iconic building that has stood across from Paris City Hall since 1856. The move prompted some French brands to announce they would leave BHV Marais, but the department store had already been losing tenants over late payments. Aime cosmetics line cofounder Mathilde Lacombe, whose brand was among those that decided to leave following