ASML Holding NV’s new advanced chip machines have a daunting price tag, said Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), one of the Dutch company’s biggest clients.

“The cost is very high,” TSMC senior vice president Kevin Zhang (張曉強) said at a technology symposium in Amsterdam on Tuesday, referring to ASML’s latest system known as high-NA extreme ultraviolet (EUV).

“I like the high-NA EUV’s capability, but I don’t like the sticker price,” Zhang said.

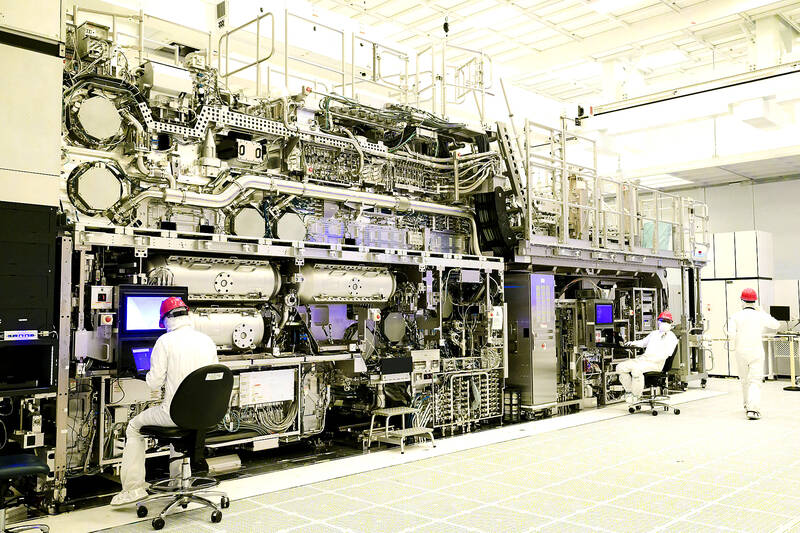

Photo: Intel Corp via Reuters

ASML’s new chip machine can imprint semiconductors with lines that are just 8 nanometers thick — 1.7 times smaller than the previous generation.

The machines cost 350 million euros (US$378 million) apiece and weigh as much as two Airbus A320s.

ASML is the only company that produces equipment needed to make the most sophisticated semiconductors, and demand for its products is a bellwether for the industry’s health.

Intel Corp has already placed orders for the latest high-NA EUV machine and got the first one shipped to a factory in Oregon in late December last year, but it is not yet clear when TSMC would start buying the equipment.

Zhang said TSMC’s so-called A16 node technology, which is due in late 2026, would not need to use ASML’s high-NA EUV machines and can continue to rely on TSMC’s older EUV equipment.

“I think at this point, our existing EUV capability should be able to support that,” he said.

Using the new ASML technology would depend on where it makes the most economic sense and “the technical balancing we can achieve,” Zhang said.

He declined to comment on when the firm would start ordering high-NA EUV machines from ASML.

Rising costs and technical complexity are making the most advanced chipmaking more difficult. Intel faces particular challenges as it tries to regain its once-unshakable technological edge.

It is also pushing into the foundry market — selling outsourced chip manufacturing — an area where TSMC dominates.

Intel on Monday announced a new general manager for its foundry services, already the third chief of the unit since it was founded in 2021.

Zhang said the costs of running a factory, including construction, tools, electricity and raw materials, “keep going up.”

“It’s a collective challenge for the whole industry,” he said.

TAKING STOCK: A Taiwanese cookware firm in Vietnam urged customers to assess inventory or place orders early so shipments can reach the US while tariffs are paused Taiwanese businesses in Vietnam are exploring alternatives after the White House imposed a 46 percent import duty on Vietnamese goods, following US President Donald Trump’s announcement of “reciprocal” tariffs on the US’ trading partners. Lo Shih-liang (羅世良), chairman of Brico Industry Co (裕茂工業), a Taiwanese company that manufactures cast iron cookware and stove components in Vietnam, said that more than 40 percent of his business was tied to the US market, describing the constant US policy shifts as an emotional roller coaster. “I work during the day and stay up all night watching the news. I’ve been following US news until 3am

UNCERTAINTY: Innolux activated a stringent supply chain management mechanism, as it did during the COVID-19 pandemic, to ensure optimal inventory levels for customers Flat-panel display makers AUO Corp (友達) and Innolux Corp (群創) yesterday said that about 12 to 20 percent of their display business is at risk of potential US tariffs and that they would relocate production or shipment destinations to mitigate the levies’ effects. US tariffs would have a direct impact of US$200 million on AUO’s revenue, company chairman Paul Peng (彭雙浪) told reporters on the sidelines of the Touch Taiwan trade show in Taipei yesterday. That would make up about 12 percent of the company’s overall revenue. To cope with the tariff uncertainty, AUO plans to allocate its production to manufacturing facilities in

COLLABORATION: Given Taiwan’s key position in global supply chains, the US firm is discussing strategies with local partners and clients to deal with global uncertainties Advanced Micro Devices Inc (AMD) yesterday said it is meeting with local ecosystem partners, including Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), to discuss strategies, including long-term manufacturing, to navigate uncertainties such as US tariffs, as Taiwan occupies an important position in global supply chains. AMD chief executive officer Lisa Su (蘇姿丰) told reporters that Taiwan is an important part of the chip designer’s ecosystem and she is discussing with partners and customers in Taiwan to forge strong collaborations on different areas during this critical period. AMD has just become the first artificial-intelligence (AI) server chip customer of TSMC to utilize its advanced

Six years ago, LVMH’s billionaire CEO Bernard Arnault and US President Donald Trump cut the blue ribbon on a factory in rural Texas that would make designer handbags for Louis Vuitton, one of the world’s best-known luxury brands. However, since the high-profile opening, the factory has faced a host of problems limiting production, 11 former Louis Vuitton employees said. The site has consistently ranked among the worst-performing for Louis Vuitton globally, “significantly” underperforming other facilities, said three former Louis Vuitton workers and a senior industry source, who cited internal rankings shared with staff. The plant’s problems — which have not