Amkor Technology Inc plans to build a US$2 billion semiconductor advanced packaging facility in Arizona, an investment that could generate as many as 2,000 jobs and bolster the Phoenix region’s status as a US chipmaking hub.

The site, in the city of Peoria, is to start production within the next two to three years, the company said in a statement.

It will package chips made for Apple Inc at a US$40 billion fab that Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) is building in Phoenix.

Amkor is the biggest outsourced provider of semiconductor assembly and testing in the US, and its Peoria plant would be the largest outsourced advanced packaging facility in the country, it said.

Globally, Amkor competes against Taiwan’s ASE Technology Holdings Co (日月光投控) and a coterie of other Asian players, with Malaysia being the international hub for such work.

The 22-hectare Peoria facility is one of more than two dozen announced chip investments in Arizona over the past few years, including a massive expansion by Intel Corp in Chandler.

Amkor has applied for Chips Act funding, the firm said in a statement, adding that federal support would be “critical to Amkor’s project moving forward.”

US Secretary of Commerce Gina Raimondo has said her agency plans to make the first awards by the end of this year.

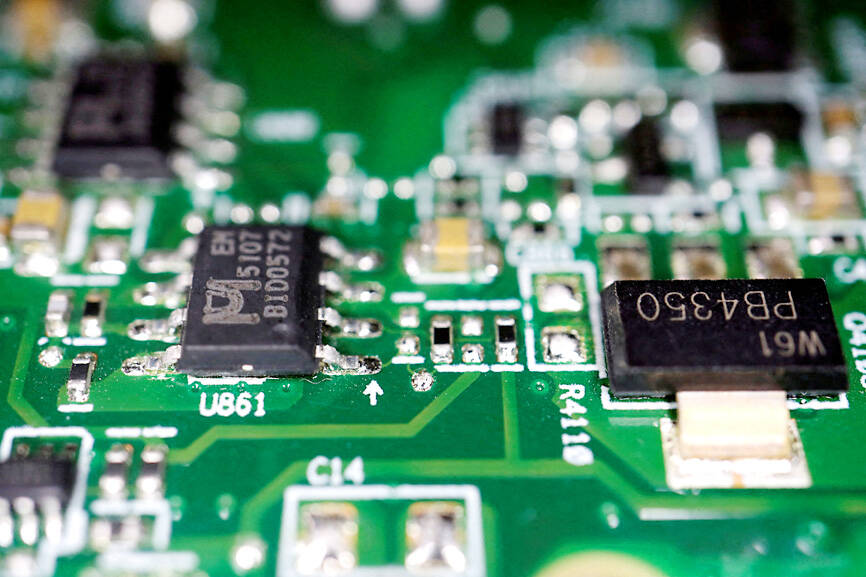

The Amkor plant would help address a lack of US capacity in packaging — the “special sauce” in chipmaking, in Raimondo’s words, that is set to become the next big chips battleground between Washington and Beijing. The US houses just 3 percent of the world’s packaging capacity compared with China’s 38 percent.

“As one of the first advanced packaging facilities in the US, this is a huge step forward to reducing dependence on other countries in the microchip supply chain,” US Senator Mark Kelly said in a statement.

Apple and TSMC also issued statements of support, citing longstanding packaging partnerships with Amkor.

“We share Amkor’s excitement for its significant investment and the value this facility will bring to TSMC, our customers and the ecosystem,” TSMC chief executive officer C.C. Wei (魏哲家) said.

In Taiwan, the company has been working closely with ASE to meet the soaring demand for its CoWoS packaging. That has proven a bottleneck, constraining supply of Nvidia Corp’s class-leading artificial intelligence accelerators.

US President Joe Biden’s administration recently outlined a US$3 billion plan to stimulate the packaging industry. As the transistors on chips become so small that they push the limits of physics, innovation in the semiconductor sector will increasingly focus on how those chips are put together.

Without localized packaging, US-made chips would still have to be shipped to Asia for assembly, creating a supply-chain risk the US “just can’t accept,” US Under Secretary of Commerce Laurie Locascio said earlier this month.

South Korea’s SK Hynix Inc has also said that it plans to invest US$15 billion in a packaging facility in the US, but the company has not selected a site.

When an apartment comes up for rent in Germany’s big cities, hundreds of prospective tenants often queue down the street to view it, but the acute shortage of affordable housing is getting scant attention ahead of today’s snap general election. “Housing is one of the main problems for people, but nobody talks about it, nobody takes it seriously,” said Andreas Ibel, president of Build Europe, an association representing housing developers. Migration and the sluggish economy top the list of voters’ concerns, but analysts say housing policy fails to break through as returns on investment take time to register, making the

‘SILVER LINING’: Although the news caused TSMC to fall on the local market, an analyst said that as tariffs are not set to go into effect until April, there is still time for negotiations US President Donald Trump on Tuesday said that he would likely impose tariffs on semiconductor, automobile and pharmaceutical imports of about 25 percent, with an announcement coming as soon as April 2 in a move that would represent a dramatic widening of the US leader’s trade war. “I probably will tell you that on April 2, but it’ll be in the neighborhood of 25 percent,” Trump told reporters at his Mar-a-Lago club when asked about his plan for auto tariffs. Asked about similar levies on pharmaceutical drugs and semiconductors, the president said that “it’ll be 25 percent and higher, and it’ll

CHIP BOOM: Revenue for the semiconductor industry is set to reach US$1 trillion by 2032, opening up opportunities for the chip pacakging and testing company, it said ASE Technology Holding Co (日月光投控), the world’s largest provider of outsourced semiconductor assembly and test (OSAT) services, yesterday launched a new advanced manufacturing facility in Penang, Malaysia, aiming to meet growing demand for emerging technologies such as generative artificial intelligence (AI) applications. The US$300 million facility is a critical step in expanding ASE’s global footprint, offering an alternative for customers from the US, Europe, Japan, South Korea and China to assemble and test chips outside of Taiwan amid efforts to diversify supply chains. The plant, the company’s fifth in Malaysia, is part of a strategic expansion plan that would more than triple

Taiwanese artificial intelligence (AI) server makers are expected to make major investments in Texas in May after US President Donald Trump’s first 100 days in office and amid his rising tariff threats, Taiwan Electrical and Electronic Manufacturers’ Association (TEEMA, 台灣電子電機公會) chairman Richard Lee (李詩欽) said yesterday. The association led a delegation of seven AI server manufacturers to Washington, as well as the US states of California, Texas and New Mexico, to discuss land and tax issues, as Taiwanese firms speed up their production plans in the US with many of them seeing Texas as their top option for investment, Lee said. The