In the quest to build better for the future, some are looking for answers in the long-ago past.

Ancient builders across the world created structures that are still standing today, thousands of years later — from Roman engineers who poured thick concrete sea barriers to Maya masons who crafted plaster sculptures to their gods and Chinese builders who raised walls against invaders.

Yet scores of more recent structures are already staring down their expiration dates: The concrete that makes up much of the modern world has a lifespan of about 50 to 100 years.

Photo: AFP

A growing number of scientists have been studying materials from long-ago eras — chipping off chunks of buildings, poring over historical texts, mixing up copycat recipes — hoping to uncover how they have held up for millennia.

This reverse engineering has turned up a surprising list of ingredients that were mixed into old buildings — materials such as tree bark, volcanic ash, rice, beer and even urine. These unexpected add-ins could be key some pretty impressive properties, such as the ability to get stronger over time and “heal” cracks when they form.

Figuring out how to copy those features could have real impacts today: While modern concrete has the strength to hold up massive skyscrapers and heavy infrastructure, it cannot compete with the endurance of these ancient materials.

With increasing threats from climate change, there is a growing call to make construction more sustainable.

A recent UN report estimated that the built environment is responsible for more than one-third of global carbon dioxide emissions — and cement production alone makes up more than 7 percent of those emissions.

“If you improve the properties of the material by using ... traditional recipes from Maya people or the ancient Chinese, you can produce material that can be used in modern construction in a much more sustainable way,” said Carlos Rodriguez-Navarro, a cultural heritage researcher at Spain’s University of Granada.

COMPARING CONCRETES

Many researchers have turned to the Romans for inspiration. Starting around 200 BC, the architects of the Roman Empire were building impressive concrete structures that have stood the test of time — from the soaring dome of the Pantheon to the sturdy aqueducts that still carry water today.

Even in harbors, where seawater has been battering structures for ages, concrete can be found “basically the way it was when it was poured 2,000 years ago,” said John Oleson, an archeologist at the University of Victoria in Canada.

Most modern concrete starts with Portland cement, a powder made by heating limestone and clay to super-high temperatures and grinding them up. That cement is mixed with water to create a chemically reactive paste. Then, chunks of material such as rock and gravel are added, and the cement paste binds them into a concrete mass.

Records from ancient architects such as Vitruvius say that the Roman process was similar. The ancient builders mixed materials such as burnt limestone and volcanic sand with water and gravel, creating chemical reactions to bind everything together.

Yet scientists think they have found a key reason why some Roman concrete has held up structures for thousands of years: The ancient material has an unusual power to repair itself. Exactly how is not yet clear, but scientists are starting to find clues.

In a study published earlier this year, Admir Masic, a civil and environmental engineer at the Massachusetts Institute of Technology, said that this power could come from chunks of lime that are studded throughout the Roman material instead of being mixed in evenly.

Researchers used to think these chunks were a sign that the Romans were not mixing up their materials well enough.

Instead, after analyzing concrete samples from Privernum — an ancient city outside of Rome — the scientists found that the chunks could fuel the material’s “self-healing” abilities.

When cracks form, water is able to seep into the concrete, Masic said.

That water activates the leftover pockets of lime, sparking up new chemical reactions that can fill in the damaged sections.

Marie Jackson, a geologist at the University of Utah, has a different take.

Her research has found that the key could be in the specific volcanic materials used by the Romans.

The builders would gather volcanic rocks left behind after eruptions to mix into their concrete.

This naturally reactive material changes over time as it interacts with the element, enabling it to seal cracks that develop, Jackson said.

The ability to keep adapting over time “is truly the genius of the material,” Jackson said. “The concrete was so well designed that it sustains itself.”

SUPER SCULPTURES

At Copan, a Maya site in Honduras, intricate lime sculptures and temples remain intact even after more than 1,000 years exposed to a hot, humid environment.

A study published earlier this year said that the secret to these structures’ longevity might lie in the trees that sprout among them.

Researchers here had a living link to the structures’ creators: They met with local masons in Honduras who traced their lineage all the way back to the Maya builders, said Rodriguez-Navarro, who worked on the study.

The masons suggested using extracts from local chukum and jiote trees in the lime mix. When researchers tested out the recipe — collecting bark, putting the chunks in water and adding the resulting tree “juice” into the material — they found that the resulting plaster was especially durable against physical and chemical damage.

When scientists zoomed in, they saw that bits of organic material from the tree juice got incorporated into the plaster’s molecular structure.

In this way, the Mayan plaster was able to mimic sturdy natural structures such as seashells and sea urchin spines — and borrow some of their toughness, Rodriguez-Navarro said.

Studies have found all kinds of natural materials mixed into structures from long ago: fruit extracts, milk, cheese curd, beer, and even dung and urine. The mortar that holds together some of China’s most famous structures — including the Great Wall and the Forbidden City — includes traces of starch from sticky rice.

LUCK OR SKILL?

Some of these ancient builders might have just gotten lucky, said Cecilia Pesce, a materials scientist at the University of Sheffield in England.

They would toss just about anything into their mixes, as long as it was cheap and available — and the ones that did not work out have long since collapsed.

“They would put all sorts of things in construction,” Pesce said. “And now, we only have the buildings that survived, so it’s like a natural selection process.”

However, some materials seem to show more intention — such as in India, where builders crafted blends of local materials to produce different properties, said Thirumalini Selvaraj, a civil engineer and professor at India’s Vellore Institute of Technology.

Selvaraj’s research found that in the humid areas of India, builders used local herbs that help structures deal with moisture.

Along the coast, they added jaggery, an unrefined sugar, which can help protect from salt damage, and in areas with higher earthquake risks, they used super-light “floating bricks” made with rice husks.

“They know the region, they know the soil condition, they know the climate, so they engineer a material according to this,” Selvaraj said.

SKY NOT THE LIMIT

Today’s builders cannot just copy the ancient recipes. Even though Roman concrete lasted a long time, it could not hold up heavy loads.

“You couldn’t build a modern skyscraper with Roman concrete,” Oleson said. “It would collapse when you got to the third story.”

Instead, researchers are trying to take some of the ancient material’s specialties and add them into modern mixes.

Masic is part of a start-up that is trying to build new projects using Roman-inspired, “self-healing” concrete, and Jackson is working with the Army Corps of Engineers to design concrete structures that can hold up well in seawater — like the ones in Roman ports — to help protect coastlines from sea level rise.

Things do not need to be made to last quite as long as the Romans did to have an effect, Masic said.

If 50 or 100 years were added to concrete’s lifespan, “we will require less demolition, less maintenance and less material in the long run,” he said.

Hon Hai Precision Industry Co (鴻海精密) yesterday said that its research institute has launched its first advanced artificial intelligence (AI) large language model (LLM) using traditional Chinese, with technology assistance from Nvidia Corp. Hon Hai, also known as Foxconn Technology Group (富士康科技集團), said the LLM, FoxBrain, is expected to improve its data analysis capabilities for smart manufacturing, and electric vehicle and smart city development. An LLM is a type of AI trained on vast amounts of text data and uses deep learning techniques, particularly neural networks, to process and generate language. They are essential for building and improving AI-powered servers. Nvidia provided assistance

DOMESTIC SUPPLY: The probe comes as Donald Trump has called for the repeal of the US$52.7 billion CHIPS and Science Act, which the US Congress passed in 2022 The Office of the US Trade Representative is to hold a hearing tomorrow into older Chinese-made “legacy” semiconductors that could heap more US tariffs on chips from China that power everyday goods from cars to washing machines to telecoms equipment. The probe, which began during former US president Joe Biden’s tenure in December last year, aims to protect US and other semiconductor producers from China’s massive state-driven buildup of domestic chip supply. A 50 percent US tariff on Chinese semiconductors began on Jan. 1. Legacy chips use older manufacturing processes introduced more than a decade ago and are often far simpler than

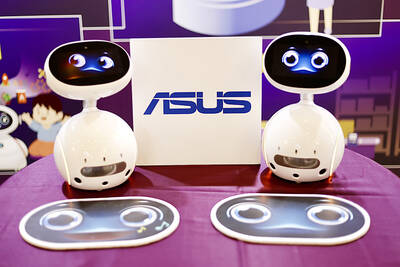

STILL HOPEFUL: Delayed payment of NT$5.35 billion from an Indian server client sent its earnings plunging last year, but the firm expects a gradual pickup ahead Asustek Computer Inc (華碩), the world’s No. 5 PC vendor, yesterday reported an 87 percent slump in net profit for last year, dragged by a massive overdue payment from an Indian cloud service provider. The Indian customer has delayed payment totaling NT$5.35 billion (US$162.7 million), Asustek chief financial officer Nick Wu (吳長榮) told an online earnings conference. Asustek shipped servers to India between April and June last year. The customer told Asustek that it is launching multiple fundraising projects and expected to repay the debt in the short term, Wu said. The Indian customer accounted for less than 10 percent to Asustek’s

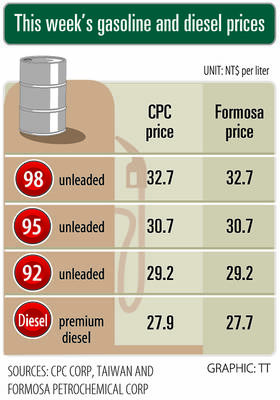

Gasoline and diesel prices this week are to decrease NT$0.5 and NT$1 per liter respectively as international crude prices continued to fall last week, CPC Corp, Taiwan (CPC, 台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. Effective today, gasoline prices at CPC and Formosa stations are to decrease to NT$29.2, NT$30.7 and NT$32.7 per liter for 92, 95 and 98-octane unleaded gasoline respectively, while premium diesel is to cost NT$27.9 per liter at CPC stations and NT$27.7 at Formosa pumps, the companies said in separate statements. Global crude oil prices dropped last week after the eight OPEC+ members said they would