Applied Materials Inc is planning to spend as much as US$4 billion on a new research and development (R&D) center near its California headquarters, embarking on a now-rare building project in the heart of Silicon Valley.

The Equipment and Process Innovation and Commercialization (EPIC) Center on Applied Materials’ campus in Santa Clara would be the biggest R&D facility in the semiconductor industry, the company said yesterday.

Applied Materials is the largest maker of chip-manufacturing equipment, and the project would let the firm and its customers rapidly develop new production techniques.

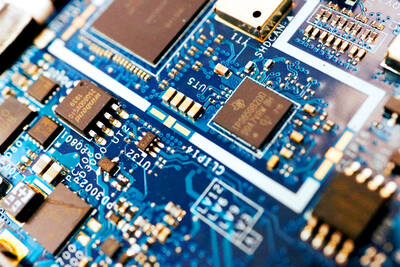

Photo: Reuters / Applied Materials Inc

Like many of the industry’s construction projects these days, the effort is also a bid to tap government funding. The US’ CHIPS and Science Act, passed last year, is to allocate roughly US$52 billion to help revitalize domestic R&D and manufacturing, and companies are angling to benefit from the windfall.

Applied Materials’ ambitions with the new center would hinge on how much assistance it gets, CEO Gary Dickerson said in an interview.

“The scale and pace of what we do is dependent on incentives,” he said.

The company chose to build in Silicon Valley — a place that has become too costly and burdensome for most new chip facilities — because of the proximity to many companies with an interest in semiconductors, he said.

Intel Corp, Nvidia Corp and Advanced Micro Devices Inc are all based in the city, about an hour’s drive south of San Francisco.

The new facility is designed to speed up improvements in the way that semiconductors are made, helping the chip business grow into a trillion-dollar market this decade.

The EPIC Center, whose name is short for equipment and process innovation and commercialization, would let chip manufacturers try out new machinery in something close to a complete production line. That should make it faster and easier to fine-tune new production technologies.

At the same time, academic institutions would have access to cutting-edge gear for research, Dickerson said.

The overall aim is to cut down on the 10 to 15 years that it takes academic research to make it to the factory floor.

The center would also help attract and train the workers that the industry needs to run plants and design chips, he said.

Dickerson said that the project is needed to help overcome daunting new technical challenges and maintain the pace of chip advancement — what he calls one of humankind’s greatest engineering achievements.

A state-of-the-art chip crams 96.5km of wiring connecting 15 billion transistors into an area that is 10 millimeters across. Some of the layers of materials deposited to create that structure are only four atoms deep.

Building the new facility would lead to an increase in Applied Materials’ capital spending over the next few years, but the company has said that its investments would not affect its ability to fund dividends and share repurchases.

GREAT SUCCESS: Republican Senator Todd Young expressed surprise at Trump’s comments and said he expects the administration to keep the program running US lawmakers who helped secure billions of dollars in subsidies for domestic semiconductor manufacturing rejected US President Donald Trump’s call to revoke the 2022 CHIPS and Science Act, signaling that any repeal effort in the US Congress would fall short. US Senate Minority Leader Chuck Schumer, who negotiated the law, on Wednesday said that Trump’s demand would fail, while a top Republican proponent, US Senator Todd Young, expressed surprise at the president’s comments and said he expects the administration to keep the program running. The CHIPS Act is “essential for America leading the world in tech, leading the world in AI [artificial

DOMESTIC SUPPLY: The probe comes as Donald Trump has called for the repeal of the US$52.7 billion CHIPS and Science Act, which the US Congress passed in 2022 The Office of the US Trade Representative is to hold a hearing tomorrow into older Chinese-made “legacy” semiconductors that could heap more US tariffs on chips from China that power everyday goods from cars to washing machines to telecoms equipment. The probe, which began during former US president Joe Biden’s tenure in December last year, aims to protect US and other semiconductor producers from China’s massive state-driven buildup of domestic chip supply. A 50 percent US tariff on Chinese semiconductors began on Jan. 1. Legacy chips use older manufacturing processes introduced more than a decade ago and are often far simpler than

Hon Hai Precision Industry Co (鴻海精密) yesterday said that its research institute has launched its first advanced artificial intelligence (AI) large language model (LLM) using traditional Chinese, with technology assistance from Nvidia Corp. Hon Hai, also known as Foxconn Technology Group (富士康科技集團), said the LLM, FoxBrain, is expected to improve its data analysis capabilities for smart manufacturing, and electric vehicle and smart city development. An LLM is a type of AI trained on vast amounts of text data and uses deep learning techniques, particularly neural networks, to process and generate language. They are essential for building and improving AI-powered servers. Nvidia provided assistance

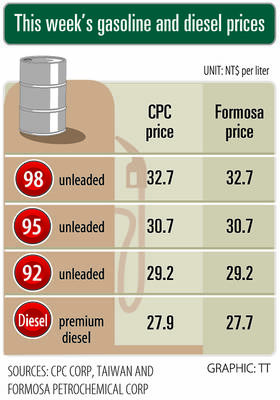

Gasoline and diesel prices this week are to decrease NT$0.5 and NT$1 per liter respectively as international crude prices continued to fall last week, CPC Corp, Taiwan (CPC, 台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. Effective today, gasoline prices at CPC and Formosa stations are to decrease to NT$29.2, NT$30.7 and NT$32.7 per liter for 92, 95 and 98-octane unleaded gasoline respectively, while premium diesel is to cost NT$27.9 per liter at CPC stations and NT$27.7 at Formosa pumps, the companies said in separate statements. Global crude oil prices dropped last week after the eight OPEC+ members said they would