The UK is committing £1 billion (US$1.24 billion) to bolstering its domestic semiconductor industry over the next decade, funding a long-anticipated strategy to engage in the battle for dominance in the global chips market.

The investment is a fraction of what other governments have pledged to the sector after COVID-19 pandemic-era shortages upended global supply chains and underscored the world’s reliance on Asia for chips used in everything from mobile phones to laptops and other home electronics.

The US and the EU have in recent months pledged about US$50 billion and 43 billion euros (US$46.5 billion) respectively to spur manufacturing in their regions.

The UK’s plan is to home in on areas of the sector where the government believes the kingdom already has a comparative advantage rather than go head-to-head with governments throwing far more money at the industry as a whole.

“Our new strategy focuses our efforts on where our strengths lie, in areas like research and design,” British Prime Minister Rishi Sunak said.

Global chip supply disruptions brought on by COVID-19 restrictions touched off a race among major economies to secure inventories, protect their proprietary technologies and make more semiconductors at home.

The US, in particular, has aggressively targeted China’s efforts to advance its semiconductor technologies, blocking US companies from providing certain equipment and services to the country.

The UK Department for Science, Innovation and Technology said the government’s investments would focus on areas including research and semiconductor design. Britain is already home to Arm Ltd, Softbank Group Corp’s prized chip designer.

The UK is also targeting compound semiconductors, made of combinations of elements with properties deemed promising in emerging technologies such as 5G, electric vehicles and facial recognition.

The government said the investment would expand the domestic sector, protect national security and mitigate the risk of supply chain disruptions.

However, the chips most critical to day-to-day applications would still come from overseas — particularly from Taiwan, home to the world’s leading supplier of chips.

The UK will “increase its cooperation with close partners” to develop supply chain resilience, it said.

The UK’s total, 10-year funding commitment is less than what the world’s leading chip foundry company, Taiwan Semiconductor Manufacturing Co (台積電), spends every two weeks.

The UK government has been facing increasing pressure to lay out a strategy as other nations take aggressive measures to secure their own supplies.

Meanwhile, signs have emerged that Britain’s own industry is moving into foreign ownership.

Arm, for example, decided to list in the US instead of London.

In 2021, US chip giant Intel Corp told the BBC it had ruled out the UK as a location for a new plant because of Brexit.

The opposition Labour Party’s Lucy Powell blasted the strategy, saying that it would be “met with disappointment by the scale of its ambition.”

Following Arm’s decision to list in the US, she said: “This strategy offers little assurance we can maintain and grow an industry vital for growth and national security.”

Hon Hai Precision Industry Co (鴻海精密) yesterday said that its research institute has launched its first advanced artificial intelligence (AI) large language model (LLM) using traditional Chinese, with technology assistance from Nvidia Corp. Hon Hai, also known as Foxconn Technology Group (富士康科技集團), said the LLM, FoxBrain, is expected to improve its data analysis capabilities for smart manufacturing, and electric vehicle and smart city development. An LLM is a type of AI trained on vast amounts of text data and uses deep learning techniques, particularly neural networks, to process and generate language. They are essential for building and improving AI-powered servers. Nvidia provided assistance

GREAT SUCCESS: Republican Senator Todd Young expressed surprise at Trump’s comments and said he expects the administration to keep the program running US lawmakers who helped secure billions of dollars in subsidies for domestic semiconductor manufacturing rejected US President Donald Trump’s call to revoke the 2022 CHIPS and Science Act, signaling that any repeal effort in the US Congress would fall short. US Senate Minority Leader Chuck Schumer, who negotiated the law, on Wednesday said that Trump’s demand would fail, while a top Republican proponent, US Senator Todd Young, expressed surprise at the president’s comments and said he expects the administration to keep the program running. The CHIPS Act is “essential for America leading the world in tech, leading the world in AI [artificial

DOMESTIC SUPPLY: The probe comes as Donald Trump has called for the repeal of the US$52.7 billion CHIPS and Science Act, which the US Congress passed in 2022 The Office of the US Trade Representative is to hold a hearing tomorrow into older Chinese-made “legacy” semiconductors that could heap more US tariffs on chips from China that power everyday goods from cars to washing machines to telecoms equipment. The probe, which began during former US president Joe Biden’s tenure in December last year, aims to protect US and other semiconductor producers from China’s massive state-driven buildup of domestic chip supply. A 50 percent US tariff on Chinese semiconductors began on Jan. 1. Legacy chips use older manufacturing processes introduced more than a decade ago and are often far simpler than

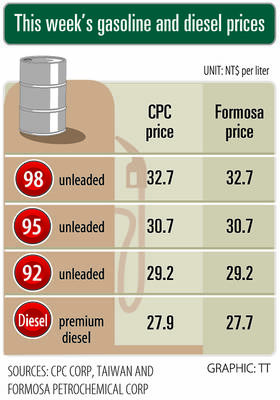

Gasoline and diesel prices this week are to decrease NT$0.5 and NT$1 per liter respectively as international crude prices continued to fall last week, CPC Corp, Taiwan (CPC, 台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. Effective today, gasoline prices at CPC and Formosa stations are to decrease to NT$29.2, NT$30.7 and NT$32.7 per liter for 92, 95 and 98-octane unleaded gasoline respectively, while premium diesel is to cost NT$27.9 per liter at CPC stations and NT$27.7 at Formosa pumps, the companies said in separate statements. Global crude oil prices dropped last week after the eight OPEC+ members said they would