Apple Inc added three Taiwanese manufacturers to its supplier list in the past fiscal year, while many others, such as iPhone assembler Hon Hai Precision Industry Co (鴻海精密), IC packaging and testing services provider ASE Technology Holding Co (日月光投控) and contract chipmaker Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), remained on the list.

On the list released for the year ending September last year, metal powder injection molding device maker Taiwan Powder Technologies Co (台耀科技), membrane touch switch supplier Ko Ja (Cayman) Co (科嘉) and LCD surface-mount technology production solutions provider Taiwan Surface Mounting Technology Corp (台灣表面黏著科技) were added.

As for Hon Hai, about 40 percent of its sales come from Apple. The manufacturer has production sites in China’s Guangdong, Henan, Hubei, Jiangsu, Shaanxi, Sichuan and Zhejiang provinces, Brazil’s Amasonas state and Sao Paulo, India’s Tamil Nadu state, the US states of California and Texas, and Vietnam’s Bac Giang Province on the Apple supplier list.

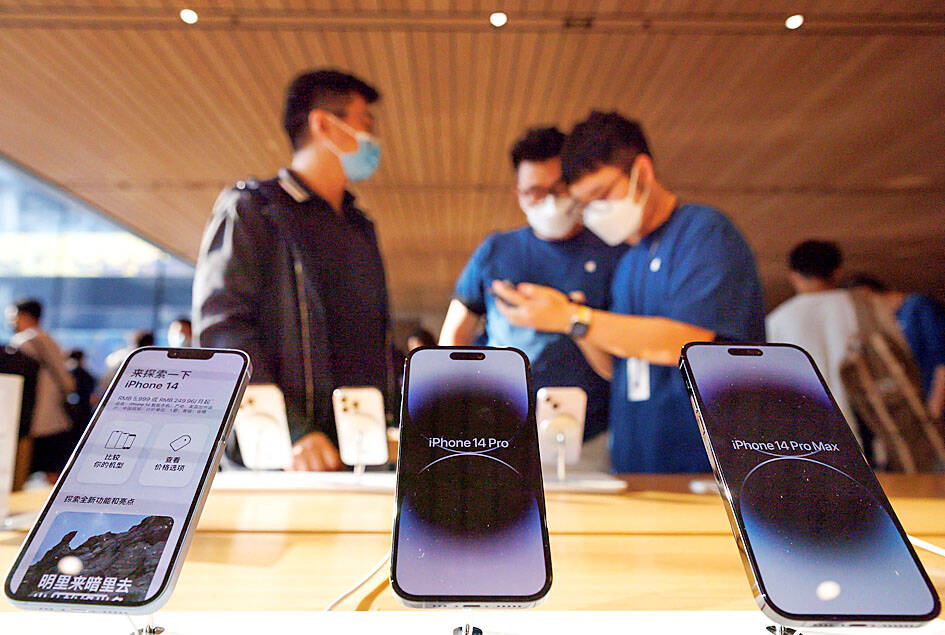

Photo: Reuters

Hon Hai, also known as Foxconn Technology Group (富士康科技集團), produces iPhones at its Zhengzhou complex in Henan, while its production compound in Shenzhen is involved in development and new product introduction for iPhones, analysts said.

ASE’s production sites in Kaohsiung, Taoyuan and Nantou County, China’s Jiangsu and Shanghai, Japan’s Yamagata Prefecture, South Korea’s Gyeonggi Province, Singapore and Vietnam’s Haiphong are on the Apple supplier list. ASE is the world’s largest IC packaging and testing provider.

TSMC, the world’s largest contract chipmaker, is believed to serve as the sole supplier of chips for iPhone production, as Apple is one of its largest clients.

Other Taiwanese manufacturers on the list included smartphone camera lens suppliers Largan Precision Co (大立光) and Genius Electronic Optical Co (玉晶光), power management solution provider Delta Electronics Inc (台達電子), metal casing supplier Catcher Technology Co (可成科技), Hon Hai’s resistor subsidiary Cheng Uei Precision Industry Co (正崴精密), and contract notebook computer makers Compal Electronics Inc (仁寶電腦) and Inventec Corp (英業達).

Smaller Taiwanese iPhone assemblers Pegatron Corp (和碩) and Wistron Corp (緯創), the world’s third-largest multilayer ceramic capacitor maker, Yageo Corp (國巨), DRAM chip supplier Nanya Technology Corp (南亞科技), printed circuit board supplier Compeq Manufacturing Co (華通電腦) and Unimicron Technology Corp (欣興電子), one of Taiwan’s major suppliers of Ajinomoto build-up film, are also on the list.

Separately, iPhone exports from India exceeded US$1 billion in the five months since April, people familiar with the matter said, signaling that the South Asian nation is making progress with its bid to become a force in electronics manufacturing.

At the current rate, outbound shipments of India-made iPhones, mainly to Europe and the Middle East, are set to reach US$2.5 billion in the 12 months through March next year, the people said, asking not to be named as the data are not public.

That is almost double the US$1.3 billion worth of iPhones India exported in the year through March this year, the people said.

Apple’s key Taiwanese contract manufacturers Hon Hai, Wistron and Pegatron make iPhones at plants in Southern India. All three won manufacturing incentives under a federal government plan.

However, India is still far behind China. About 3 million iPhones were made in India last year, compared with 230 million in China, Bloomberg Intelligence estimates showed.

The devices exported from India from April to August comprise iPhone 11, 12 and 13 models, and exports of the new iPhone 14 line are to begin soon, the people said.

Beyond smartphones, India is drawing up plans to boost financial incentives for tablet and laptop makers, hoping to woo Apple to make MacBooks and iPads locally, and attract other brands.

The New Taiwan dollar is on the verge of overtaking the yuan as Asia’s best carry-trade target given its lower risk of interest-rate and currency volatility. A strategy of borrowing the New Taiwan dollar to invest in higher-yielding alternatives has generated the second-highest return over the past month among Asian currencies behind the yuan, based on the Sharpe ratio that measures risk-adjusted relative returns. The New Taiwan dollar may soon replace its Chinese peer as the region’s favored carry trade tool, analysts say, citing Beijing’s efforts to support the yuan that can create wild swings in borrowing costs. In contrast,

Nvidia Corp’s demand for advanced packaging from Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) remains strong though the kind of technology it needs is changing, Nvidia CEO Jensen Huang (黃仁勳) said yesterday, after he was asked whether the company was cutting orders. Nvidia’s most advanced artificial intelligence (AI) chip, Blackwell, consists of multiple chips glued together using a complex chip-on-wafer-on-substrate (CoWoS) advanced packaging technology offered by TSMC, Nvidia’s main contract chipmaker. “As we move into Blackwell, we will use largely CoWoS-L. Of course, we’re still manufacturing Hopper, and Hopper will use CowoS-S. We will also transition the CoWoS-S capacity to CoWos-L,” Huang said

Nvidia Corp CEO Jensen Huang (黃仁勳) is expected to miss the inauguration of US president-elect Donald Trump on Monday, bucking a trend among high-profile US technology leaders. Huang is visiting East Asia this week, as he typically does around the time of the Lunar New Year, a person familiar with the situation said. He has never previously attended a US presidential inauguration, said the person, who asked not to be identified, because the plans have not been announced. That makes Nvidia an exception among the most valuable technology companies, most of which are sending cofounders or CEOs to the event. That includes

INDUSTRY LEADER: TSMC aims to continue outperforming the industry’s growth and makes 2025 another strong growth year, chairman and CEO C.C. Wei says Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), a major chip supplier to Nvidia Corp and Apple Inc, yesterday said it aims to grow revenue by about 25 percent this year, driven by robust demand for artificial intelligence (AI) chips. That means TSMC would continue to outpace the foundry industry’s 10 percent annual growth this year based on the chipmaker’s estimate. The chipmaker expects revenue from AI-related chips to double this year, extending a three-fold increase last year. The growth would quicken over the next five years at a compound annual growth rate of 45 percent, fueled by strong demand for the high-performance computing