A global chip supply crunch is expected to ease next year, following a series of capacity expansions by foundry service providers over a three-year period to next year, the Market Intelligence and Consulting Institute (MIC, 產業情報研究所) said on Wednesday.

The world’s foundry services providers led by Taiwan Semiconductor Manufacturing Co (TSMC, 台積電) are to boost capacity by 10 percent this year and 7 percent next year, after experiencing 10 percent annual growth last year, the Taipei-based institute said.

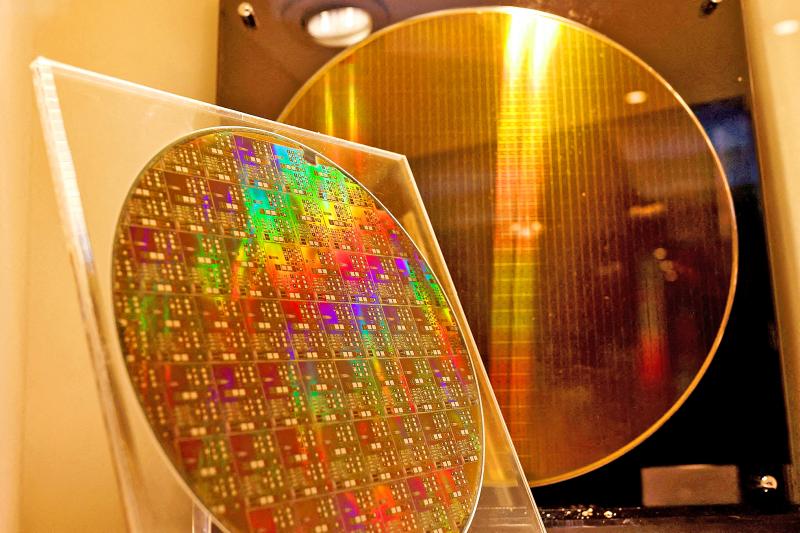

The global output of 8-inch wafers is to increase to 10 million units per month next year, up about 25 percent from fewer than 8 million units in 2020, it forecast.

Photo: Reuters

The imbalance in chip supply and demand became evident last year as the stay-at-home economy, driven by the COVID-19 pandemic, boosted demand for notebook computers, coupled with demand for smartphones and vehicles, MIC senior analyst Cheng Kai-an (鄭凱安) said at a virtual technology forum.

“As global foundry service providers continue expanding capacity, we expect semiconductor supply to become stable gradually in 2023,” Cheng said.

With slowing demand for PCs and consumer electronics this year due to high inflation, and the economic effects from COVID-19 and Russia’s invasion of Ukraine, chip supply surplus may return in 2024, he said.

Chipmakers should carefully adjust their capacity increases to cope with short-term oversupply, he added.

Chip designers started to feel the pinch of slumping demand for smartphones and consumer electronics in the first half of this year, leading to falling demand for display driver ICs used in smartphones and TVs, Cheng said.

Chip designers are scaling back orders with their foundry partners as a result, but supply of power management ICs and microcontrollers remains insufficient, he said.

In the long term, 5G-related devices, high-performance computing applications and automotive electronics are expected to continue driving semiconductor demand and growth, Cheng said.

Chinese chipmakers are boosting capacity faster than their global peers, benefiting from Chinese government funding, as Beijing seeks to reach 70 percent of chip self-sufficiency by 2025, the institute said.

However, that target is impractical, as China is expected to boost chip supply within the country to 19.4 percent in 2025, from 15.9 percent in 2020, Cheng said, citing data from semiconductor market research firm IC Insights.

Rapid capacity expansion boosted China’s ranking to No. 1 in the world’s foundry industry last year, with a market share of 22.6 percent, the MIC said.

Taiwan was No. 2 with an 18.9 percent share, followed by South Korea with 17.3 percent, MIC data showed.

Local semiconductor companies’ production value is expected to grow 17.5 percent annually to NT$4.37 trillion this year, outpacing the world semiconductor industry’s 10.4 percent growth, the MIC said.

Application-specific integrated circuit designer Faraday Technology Corp (智原) yesterday said that although revenue this quarter would decline 30 percent from last quarter, it retained its full-year forecast of revenue growth of 100 percent. The company attributed the quarterly drop to a slowdown in customers’ production of chips using Faraday’s advanced packaging technology. The company is still confident about its revenue growth this year, given its strong “design-win” — or the projects it won to help customers design their chips, Faraday president Steve Wang (王國雍) told an online earnings conference. “The design-win this year is better than we expected. We believe we will win

Intel Corp chief executive officer Lip-Bu Tan (陳立武) is expected to meet with Taiwanese suppliers next month in conjunction with the opening of the Computex Taipei trade show, supply chain sources said on Monday. The visit, the first for Tan to Taiwan since assuming his new post last month, would be aimed at enhancing Intel’s ties with suppliers in Taiwan as he attempts to help turn around the struggling US chipmaker, the sources said. Tan is to hold a banquet to celebrate Intel’s 40-year presence in Taiwan before Computex opens on May 20 and invite dozens of Taiwanese suppliers to exchange views

Chizuko Kimura has become the first female sushi chef in the world to win a Michelin star, fulfilling a promise she made to her dying husband to continue his legacy. The 54-year-old Japanese chef regained the Michelin star her late husband, Shunei Kimura, won three years ago for their Sushi Shunei restaurant in Paris. For Shunei Kimura, the star was a dream come true. However, the joy was short-lived. He died from cancer just three months later in June 2022. He was 65. The following year, the restaurant in the heart of Montmartre lost its star rating. Chizuko Kimura insisted that the new star is still down

While China’s leaders use their economic and political might to fight US President Donald Trump’s trade war “to the end,” its army of social media soldiers are embarking on a more humorous campaign online. Trump’s tariff blitz has seen Washington and Beijing impose eye-watering duties on imports from the other, fanning a standoff between the economic superpowers that has sparked global recession fears and sent markets into a tailspin. Trump says his policy is a response to years of being “ripped off” by other countries and aims to bring manufacturing to the US, forcing companies to employ US workers. However, China’s online warriors