Quanta Shanghai Manufacturing City (QSMC, 廣達上海製造城) would seem like an ideal site to implement China’s “closed loop” management system, meant to prevent the spread of COVID-19, that requires staff to live and work on-site in a secure bubble.

Sprawled over land the size of 20 football fields, the campus houses factories, living quarters for 40,000 workers and a supermarket.

Yet as COVID-19 breached Quanta’s defenses, the system turned into chaos on Thursday.

Photo: Screenshot from Quanta’s Web site

Videos posted online showed more than 100 Quanta workers physically overwhelming security guards in hazmat suits and vaulting over factory gates to avoid being trapped inside the factory amid rumors that workers that day tested positive for the virus.

The turmoil at Quanta underscores the struggles Shanghai faces to get its factories, many of them key links in global supply chains, back up to speed, even as much of the city remains locked down under China’s “zero COVID” policy.

Taiwan-based Quanta Computer Inc (廣達電腦) assembles about three-quarters of Apple Inc’s global MacBook production, and also makes circuit boards for Tesla Inc.

Quanta set up a closed loop to restart work at the factory on April 18 using about 5 percent of its workers, or 2,000 employees, with plans to triple that by April 22.

Chinese state media touted the restart as an example of how Shanghai was keeping business running while adhering to stringent COVID-19 measures.

However, cases have been reported daily at an address belonging to the campus from March 26 to Wednesday, Shanghai government data showed.

Calls seeking help to bring attention to positive cases that were not being isolated at Quanta began appearing on Weibo from April 6, five days after Shanghai implemented a city-wide lockdown.

Employees began posting photos and reports on Douyin (抖音), known as TikTok outside China, showing dozens of workers lining up for buses to be taken to central quarantine facilities.

They also took videos of themselves resting in Shanghai’s National Exhibition and Convention Center, one of the city’s largest quarantine centers, as well as at a facility purpose-built to house Quanta workers.

Two employees and a person with knowledge of the campus’ operations said there were multiple infections there.

“Each dormitory reported a few positive cases a day, and eventually everyone became positive,” said one of the two workers, who gave his surname as Li (李), adding that there were eight cases in his room, including himself.

Employees said that cases were often not isolated for days after testing positive, and one source said there were not enough isolation spaces, resulting in infections.

That was a trigger for Thursday night’s chaos, employees said, as rumors spread that positive cases had been found in the factories.

The workers were spooked by an order telling them not to return to their dormitories, raising fears that they could be locked down inside the plant.

While videos of the confrontation were removed, discussion continued online, with one user simply saying: “What a mess.”

Hon Hai Precision Industry Co (鴻海精密) yesterday said that its research institute has launched its first advanced artificial intelligence (AI) large language model (LLM) using traditional Chinese, with technology assistance from Nvidia Corp. Hon Hai, also known as Foxconn Technology Group (富士康科技集團), said the LLM, FoxBrain, is expected to improve its data analysis capabilities for smart manufacturing, and electric vehicle and smart city development. An LLM is a type of AI trained on vast amounts of text data and uses deep learning techniques, particularly neural networks, to process and generate language. They are essential for building and improving AI-powered servers. Nvidia provided assistance

DOMESTIC SUPPLY: The probe comes as Donald Trump has called for the repeal of the US$52.7 billion CHIPS and Science Act, which the US Congress passed in 2022 The Office of the US Trade Representative is to hold a hearing tomorrow into older Chinese-made “legacy” semiconductors that could heap more US tariffs on chips from China that power everyday goods from cars to washing machines to telecoms equipment. The probe, which began during former US president Joe Biden’s tenure in December last year, aims to protect US and other semiconductor producers from China’s massive state-driven buildup of domestic chip supply. A 50 percent US tariff on Chinese semiconductors began on Jan. 1. Legacy chips use older manufacturing processes introduced more than a decade ago and are often far simpler than

STILL HOPEFUL: Delayed payment of NT$5.35 billion from an Indian server client sent its earnings plunging last year, but the firm expects a gradual pickup ahead Asustek Computer Inc (華碩), the world’s No. 5 PC vendor, yesterday reported an 87 percent slump in net profit for last year, dragged by a massive overdue payment from an Indian cloud service provider. The Indian customer has delayed payment totaling NT$5.35 billion (US$162.7 million), Asustek chief financial officer Nick Wu (吳長榮) told an online earnings conference. Asustek shipped servers to India between April and June last year. The customer told Asustek that it is launching multiple fundraising projects and expected to repay the debt in the short term, Wu said. The Indian customer accounted for less than 10 percent to Asustek’s

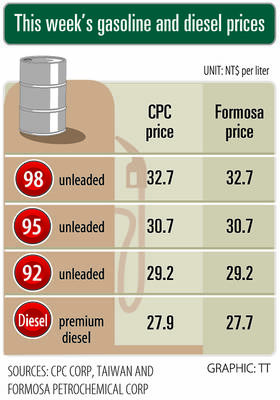

Gasoline and diesel prices this week are to decrease NT$0.5 and NT$1 per liter respectively as international crude prices continued to fall last week, CPC Corp, Taiwan (CPC, 台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. Effective today, gasoline prices at CPC and Formosa stations are to decrease to NT$29.2, NT$30.7 and NT$32.7 per liter for 92, 95 and 98-octane unleaded gasoline respectively, while premium diesel is to cost NT$27.9 per liter at CPC stations and NT$27.7 at Formosa pumps, the companies said in separate statements. Global crude oil prices dropped last week after the eight OPEC+ members said they would