Tesla Inc’s factory shutdown has stretched out to at least 12 days, much-needed semiconductors are piling up at manufacturers amid a shortage of truck drivers and bankers are camping in their offices as Shanghai’s COVID-19 lockdown disrupts businesses in the city.

The lockdowns and virus containment measures threaten to slow the nation’s economic growth this year to below the Chinese government’s 5.5 percent target, Bloomberg Economics said.

They also risk further havoc on already stressed global supply chains, with companies from chip giant Semiconductor Manufacturing International Corp (SMIC, 中芯國際) to a South Korean noodle maker caught up in the fallout.

Photo: AFP

Electric vehicle pioneer Tesla on Tuesday told some suppliers and workers that its Shanghai factory — which has been shuttered since the city went into a phased lockdown on Monday last week — would remain closed at least through today, people familiar with the matter said.

Following a separate two-day shutdown last month, Tesla has now lost 12 days of production in the past few weeks, including the Tomb Sweeping Day break.

The first Tesla Gigafactory outside the US produced half of the company’s vehicles last year. It produces not just for the lucrative Chinese market, but for export to Europe and elsewhere in Asia.

Some tech companies, including chip giants Taiwan Semiconductor Manufacturing Co (台積電) and SMIC, as well as iPhone assembler Pegatron Corp (和碩) have kept plants running by implementing a so-called closed-loop system where workers live on-site and are tested regularly.

Shanghai initially launched its two-stage lockdown starting with its eastern districts for five days, then its western districts for five days. It had been scheduled to be lifted on Tuesday.

The lockdown has since been extended to cover the entire city indefinitely.

Taiwanese businesses in Shanghai said they were making adjustments to continue operating amid the lockdown, but warned that severe logistics problems there could derail their efforts, the Central News Agency reported on Monday.

In Kunshan, which is under lockdown until tomorrow, many factories have “distributed sleeping bags” to employees and are having them work in shifts to meet production deadlines.

Still, the situation is likely to take an economic toll, an industry source said, especially among Taiwanese printed circuit board manufacturers, whose production capacity is heavily concentrated in Kunshan.

Kunshan factories account for 60 percent of the capacity of Taiwan’s Dynamic Electronics Co (定穎電子), 50 percent of the capacity of Flexium Interconnect Inc (台郡科技), 40 percent of the capacity of Nan Ya Printed Circuit Board Corp (南亞電路板), 25 percent of the capacity of Elite Material Co (EMC, 台光電子材料) and 20 percent of the capacity of Unimicron Technology Corp (欣興電子), a source said.

Of those companies, Nan Ya PCB, EMC and Unimicron have all halted operations during the lockdown, while others had already scheduled closures for Tomb Sweeping Day, thus limiting the impact on their operations, the source said.

South Korean companies are also being affected, with operations at the Shanghai plants of noodle maker Nongshim Co, confectionery manufacturer Orion Corp and cosmetics producer Amorepacific Corp suspended.

Singapore’s Spindex Industries Ltd (事必得工業), which supplies precision components used by the automobile industry, has extended the closure of its Shanghai plant until Sunday or whenever local authorities allow work to resume.

Additional reporting by CNA

Hon Hai Precision Industry Co (鴻海精密) yesterday said that its research institute has launched its first advanced artificial intelligence (AI) large language model (LLM) using traditional Chinese, with technology assistance from Nvidia Corp. Hon Hai, also known as Foxconn Technology Group (富士康科技集團), said the LLM, FoxBrain, is expected to improve its data analysis capabilities for smart manufacturing, and electric vehicle and smart city development. An LLM is a type of AI trained on vast amounts of text data and uses deep learning techniques, particularly neural networks, to process and generate language. They are essential for building and improving AI-powered servers. Nvidia provided assistance

GREAT SUCCESS: Republican Senator Todd Young expressed surprise at Trump’s comments and said he expects the administration to keep the program running US lawmakers who helped secure billions of dollars in subsidies for domestic semiconductor manufacturing rejected US President Donald Trump’s call to revoke the 2022 CHIPS and Science Act, signaling that any repeal effort in the US Congress would fall short. US Senate Minority Leader Chuck Schumer, who negotiated the law, on Wednesday said that Trump’s demand would fail, while a top Republican proponent, US Senator Todd Young, expressed surprise at the president’s comments and said he expects the administration to keep the program running. The CHIPS Act is “essential for America leading the world in tech, leading the world in AI [artificial

DOMESTIC SUPPLY: The probe comes as Donald Trump has called for the repeal of the US$52.7 billion CHIPS and Science Act, which the US Congress passed in 2022 The Office of the US Trade Representative is to hold a hearing tomorrow into older Chinese-made “legacy” semiconductors that could heap more US tariffs on chips from China that power everyday goods from cars to washing machines to telecoms equipment. The probe, which began during former US president Joe Biden’s tenure in December last year, aims to protect US and other semiconductor producers from China’s massive state-driven buildup of domestic chip supply. A 50 percent US tariff on Chinese semiconductors began on Jan. 1. Legacy chips use older manufacturing processes introduced more than a decade ago and are often far simpler than

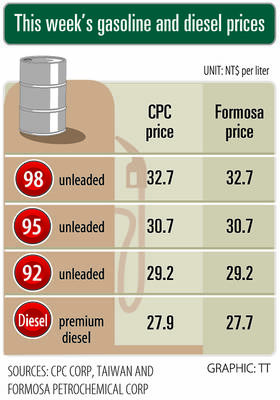

Gasoline and diesel prices this week are to decrease NT$0.5 and NT$1 per liter respectively as international crude prices continued to fall last week, CPC Corp, Taiwan (CPC, 台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. Effective today, gasoline prices at CPC and Formosa stations are to decrease to NT$29.2, NT$30.7 and NT$32.7 per liter for 92, 95 and 98-octane unleaded gasoline respectively, while premium diesel is to cost NT$27.9 per liter at CPC stations and NT$27.7 at Formosa pumps, the companies said in separate statements. Global crude oil prices dropped last week after the eight OPEC+ members said they would