Tesla Inc temporarily halted some operations at its factory in Shanghai last month as a global shortage of semiconductors hit the electric vehicle pioneer in one of its most important markets, people familiar with the matter said.

Part of a production line at the China plant was halted for about four days because of a lack of key chips, the people said, asking not to be identified because the details are private.

One particular shortage had to do with the availability of electronic control units, small devices that control one or several electrical systems in a vehicle, one of the people said.

That caused output delays mainly for Tesla’s Model Y sports utility vehicle crossover, the person said.

Production is now back to normal, the people said.

Representatives for Tesla in China did not immediately respond to a request for comment.

Intense competition for chips has affected a raft of industries over the past year, with the COVID-19 pandemic boosting demand for electronics, but interrupting supply chains.

With semiconductors now used in a vehicle’s computers, sensors and other equipment, automakers globally have lost revenue as shortages affected their output.

Toyota Motor Corp, the world’s biggest automaker, has said it cut production by 40 percent this month, while India’s largest automaker by deliveries, Maruti Suzuki India Ltd, has also said that volumes would likely drop to about 40 percent from regular levels.

On Wednesday, Chinese electric vehicle maker Nio Inc (蔚來) said that it is struggling with getting supply from manufacturing partners in Malaysia, where COVID-19 is flaring again, and China’s Nanjing.

In China, Tesla in July shipped about 33,000 vehicles locally and to overseas markets.

The Palo Alto, California-based company previously halted some production at an assembly plant in the US for about two weeks in February due to backlogs at ports and snow storms that affected ground transport.

Retail sales of vehicles in China — the world’s biggest market for electric vehicles — declined 6.4 percent in July from a year earlier to 1.52 million units, China’s Passenger Car Association statistics showed.

Preliminary data showed that last month’s sales were expected to fall 13 percent, the association said on Wednesday.

Hon Hai Precision Industry Co (鴻海精密) yesterday said that its research institute has launched its first advanced artificial intelligence (AI) large language model (LLM) using traditional Chinese, with technology assistance from Nvidia Corp. Hon Hai, also known as Foxconn Technology Group (富士康科技集團), said the LLM, FoxBrain, is expected to improve its data analysis capabilities for smart manufacturing, and electric vehicle and smart city development. An LLM is a type of AI trained on vast amounts of text data and uses deep learning techniques, particularly neural networks, to process and generate language. They are essential for building and improving AI-powered servers. Nvidia provided assistance

DOMESTIC SUPPLY: The probe comes as Donald Trump has called for the repeal of the US$52.7 billion CHIPS and Science Act, which the US Congress passed in 2022 The Office of the US Trade Representative is to hold a hearing tomorrow into older Chinese-made “legacy” semiconductors that could heap more US tariffs on chips from China that power everyday goods from cars to washing machines to telecoms equipment. The probe, which began during former US president Joe Biden’s tenure in December last year, aims to protect US and other semiconductor producers from China’s massive state-driven buildup of domestic chip supply. A 50 percent US tariff on Chinese semiconductors began on Jan. 1. Legacy chips use older manufacturing processes introduced more than a decade ago and are often far simpler than

STILL HOPEFUL: Delayed payment of NT$5.35 billion from an Indian server client sent its earnings plunging last year, but the firm expects a gradual pickup ahead Asustek Computer Inc (華碩), the world’s No. 5 PC vendor, yesterday reported an 87 percent slump in net profit for last year, dragged by a massive overdue payment from an Indian cloud service provider. The Indian customer has delayed payment totaling NT$5.35 billion (US$162.7 million), Asustek chief financial officer Nick Wu (吳長榮) told an online earnings conference. Asustek shipped servers to India between April and June last year. The customer told Asustek that it is launching multiple fundraising projects and expected to repay the debt in the short term, Wu said. The Indian customer accounted for less than 10 percent to Asustek’s

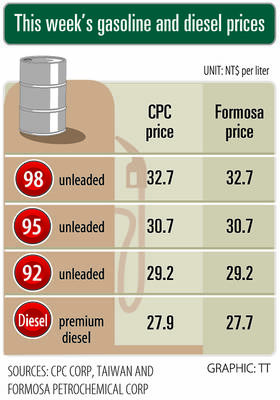

Gasoline and diesel prices this week are to decrease NT$0.5 and NT$1 per liter respectively as international crude prices continued to fall last week, CPC Corp, Taiwan (CPC, 台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. Effective today, gasoline prices at CPC and Formosa stations are to decrease to NT$29.2, NT$30.7 and NT$32.7 per liter for 92, 95 and 98-octane unleaded gasoline respectively, while premium diesel is to cost NT$27.9 per liter at CPC stations and NT$27.7 at Formosa pumps, the companies said in separate statements. Global crude oil prices dropped last week after the eight OPEC+ members said they would