Rather than exporting masks, the nation’s leading mask manufacturers plan to export turnkey mask factories as the COVID-19 pandemic continues to affect much of the world.

As a solution to unmet global demand for masks amid the pandemic, Taiwan Comfort Champ Manufacturing Co (台灣康匠) is offering a “total solution” for mask production, including the raw materials, production equipment and testing technology.

“We have miniaturized our mask production line so that it fits in a shipping container. Production can start as soon as you remove the container floor,” Taiwan Comfort Champ chairman Andy Chen (陳勇志) told a news conference in New Taipei City’s Tucheng District (土城) yesterday.

Photo: Chen Jou-chen, Taipei Times

Except for the machines that make and package the masks, the “one-stop mask factory” includes all of the equipment and technical support to produce the critical non-woven layer that serves as the mask’s filtration material, Chen said.

The news conference was organized by the government-backed Taiwan Textile Research Institute (紡織產業綜合研究所).

Each miniature mask factory costs as little as US$5 million and can produce as many as 600,000 masks per day if continuously operated, Taiwan Comfort Champ said.

Higher capacity modules capable of producing up to 2 million masks per day are also available, a company release said.

The mini-factory allows production to rapidly increase and is more environmentally friendly, Chen said.

“Keeping the entire production and packaging process in the same area saves a lot of packaging and transportation costs,” he said.

Despite the unprecedented demand for masks internationally, Taiwan Comfort Champ did not get to cash in on the opportunity because the government set pricing controls, he said.

“We had to drop a lot of foreign orders,” he added.

The company has received inquiries from the US, Canada, Indonesia, Japan and Spain, but investors tend to be hindered by technical hurdles, Taiwan Comfort Champ said, adding that the first turnkey mini factory is to be shipped to Thailand.

Hon Hai Precision Industry Co (鴻海精密) yesterday said that its research institute has launched its first advanced artificial intelligence (AI) large language model (LLM) using traditional Chinese, with technology assistance from Nvidia Corp. Hon Hai, also known as Foxconn Technology Group (富士康科技集團), said the LLM, FoxBrain, is expected to improve its data analysis capabilities for smart manufacturing, and electric vehicle and smart city development. An LLM is a type of AI trained on vast amounts of text data and uses deep learning techniques, particularly neural networks, to process and generate language. They are essential for building and improving AI-powered servers. Nvidia provided assistance

GREAT SUCCESS: Republican Senator Todd Young expressed surprise at Trump’s comments and said he expects the administration to keep the program running US lawmakers who helped secure billions of dollars in subsidies for domestic semiconductor manufacturing rejected US President Donald Trump’s call to revoke the 2022 CHIPS and Science Act, signaling that any repeal effort in the US Congress would fall short. US Senate Minority Leader Chuck Schumer, who negotiated the law, on Wednesday said that Trump’s demand would fail, while a top Republican proponent, US Senator Todd Young, expressed surprise at the president’s comments and said he expects the administration to keep the program running. The CHIPS Act is “essential for America leading the world in tech, leading the world in AI [artificial

DOMESTIC SUPPLY: The probe comes as Donald Trump has called for the repeal of the US$52.7 billion CHIPS and Science Act, which the US Congress passed in 2022 The Office of the US Trade Representative is to hold a hearing tomorrow into older Chinese-made “legacy” semiconductors that could heap more US tariffs on chips from China that power everyday goods from cars to washing machines to telecoms equipment. The probe, which began during former US president Joe Biden’s tenure in December last year, aims to protect US and other semiconductor producers from China’s massive state-driven buildup of domestic chip supply. A 50 percent US tariff on Chinese semiconductors began on Jan. 1. Legacy chips use older manufacturing processes introduced more than a decade ago and are often far simpler than

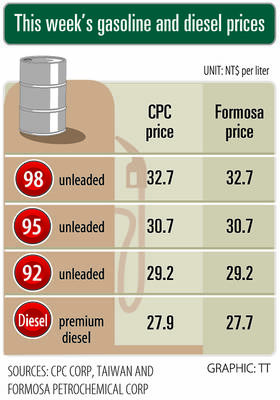

Gasoline and diesel prices this week are to decrease NT$0.5 and NT$1 per liter respectively as international crude prices continued to fall last week, CPC Corp, Taiwan (CPC, 台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. Effective today, gasoline prices at CPC and Formosa stations are to decrease to NT$29.2, NT$30.7 and NT$32.7 per liter for 92, 95 and 98-octane unleaded gasoline respectively, while premium diesel is to cost NT$27.9 per liter at CPC stations and NT$27.7 at Formosa pumps, the companies said in separate statements. Global crude oil prices dropped last week after the eight OPEC+ members said they would