Flute maker Wong Cheng-jung (汪正榮) has high ambitions. “Japanese and American flute makers lead the world,” he said. “But I want to show the world that Taiwanese flute makers can also come up with world-class flutes.”

The 53-year-old flute maker currently has his own studio in Kuandu, Taipei County. Making and fixing flutes has been his lifelong job and the only thing, Wong says, that makes him smile.

His two-story studio resembles a small factory, cluttered with machinery and what appear to be metalworking tools, though it’s difficult to immediately discern what exactly is made here. It’s only when Wong and his assistant pick up the tools and begin bending and hammering thin silver pipes that the object of Wong’s affections becomes clear.

“A ‘healthy’ flute is something that I will always insist on, no matter how much the flute is worth,” said Wong.

A healthy flute has a sound that is clean and loud, but is also well-tuned and functions normally and accurately. The finger holes are either completely open or sealed by keys when the flute is played, and there must be a good headjoint, the most important part of a flute, which is also the most difficult to make.

“This is the hardest part of the entire production process,” Wong said as he tested the headjoint he had just constructed by blowing into it, listening to the sound it made, and making adjustments. “It must fit the shape of the [player’s mouth] so when he [or she] blows into it, the air will flow smoothly from the headjoint to the rest of the flute.”

Wong then demonstrated the production of the instrument’s body. Following a manual that he calls the flutemaker’s “bible,” he installed keypads and neck screws onto a silver tube. “Whether the keys can close completely and open smoothly determines the sound the flute makes,” Wong explained. “If they do not work, you will hear the sound of air leaking from the flute as it is played.”

LOVE AT FIRST SIGHT

It takes approximately 200 hours for Wong to produce a brand new, hand-made silver flute, which could cost about NT$180,000. Although flutes can be made of wood, copper, silver or gold, according to Wong, silver is the best and most widely used material in today’s market.

Upon encountering his first harmonica when he was 14 years old, Wong fell in love with music. He first played a flute during his junior year in college. “I immediately fell in love with the musical instrument,” Wong recalls, adding that he purchased his first for NT$10,000. “I spent a lot of time practicing.”

It’s no surprise, then, that although Wong graduated from Feng Chia University with a bachelor’s degree from the Department of Water Resources Engineering and Conservation, his first job, after serving his compulsory military term, was as a flute maker at a Yamaha KHS Music Company factory in Luchou, Taipei County. “Working at KHS was the period when I learned pretty much everything about making a flute,” Wong said.

Ten years after he joined KHS, Wong left to establish his own studio, where he has been working for the past 16 years.

Although he is a flute maker, Wong does not always recommend expensive flutes. “Prices do not necessarily mean quality. As long as the flute comes with a good pipe that fits the flutist and tight seals that can completely open and close the instrument’s pinholes, it will be the best flute that a flutist can get. It does not have to be very expensive.”

THE FUTURE OF FLUTE MAKING

Nor does Wong always recommend fixing broken flutes. “If it is an expensive flute, I will do my best to fix it for my client. If it is not, I will recommend my client give it up because it usually costs more than NT$3,000 to fix a damaged flute, which can be more than what it is worth,” Wong said.

Even as he aspires to surpass his Japanese and American counterparts, Wong is also worried that the skills he knows will be lost someday, as fewer and fewer people take the time to learn the craft of flute making. “To make a good pipe for the flute, it takes time and experience to test, test and test. This part is not written down in black and white and cannot be described, either. It takes a lot of trial and error before a flute maker can really become a master,” Wong said. “Also, most parents would expect their children to become remarkable flutists, instead of flute makers.”

Flutist James Lin (林仁斌), who has been one of Wong’s regular customers for 20 years, calls Wong a “master” of flute making. “What is so special about him is that he has respect for artists,” Lin said.

The 37-year-old flutist said that Wong always insists on making flutes that fit his customers’ needs. “Every hand-made flute has its own character. Wong is capable of making the unique character of each flute fit what its owner needs.” Lin added, “In addition to the term ‘healthy,’ I think ‘pure’ should be another good word to describe his [Wong’s] flutes.”

According to Lin, “preciseness” is the most important of a flute’s attributes. “I always feel like I am in total control of the flute, whenever I am playing one of his products,” Lin said.

A vaccine to fight dementia? It turns out there may already be one — shots that prevent painful shingles also appear to protect aging brains. A new study found shingles vaccination cut older adults’ risk of developing dementia over the next seven years by 20 percent. The research, published Wednesday in the journal Nature, is part of growing understanding about how many factors influence brain health as we age — and what we can do about it. “It’s a very robust finding,” said lead researcher Pascal Geldsetzer of Stanford University. And “women seem to benefit more,” important as they’re at higher risk of

Eric Finkelstein is a world record junkie. The American’s Guinness World Records include the largest flag mosaic made from table tennis balls, the longest table tennis serve and eating at the most Michelin-starred restaurants in 24 hours in New York. Many would probably share the opinion of Finkelstein’s sister when talking about his records: “You’re a lunatic.” But that’s not stopping him from his next big feat, and this time he is teaming up with his wife, Taiwanese native Jackie Cheng (鄭佳祺): visit and purchase a

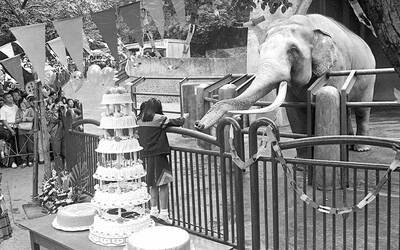

April 7 to April 13 After spending over two years with the Republic of China (ROC) Army, A-Mei (阿美) boarded a ship in April 1947 bound for Taiwan. But instead of walking on board with his comrades, his roughly 5-tonne body was lifted using a cargo net. He wasn’t the only elephant; A-Lan (阿蘭) and A-Pei (阿沛) were also on board. The trio had been through hell since they’d been captured by the Japanese Army in Myanmar to transport supplies during World War II. The pachyderms were seized by the ROC New 1st Army’s 30th Division in January 1945, serving

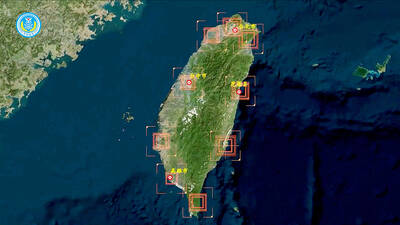

The People’s Republic of China (PRC) last week offered us a glimpse of the violence it plans against Taiwan, with two days of blockade drills conducted around the nation and live-fire exercises not far away in the East China Sea. The PRC said it had practiced hitting “simulated targets of key ports and energy facilities.” Taiwan confirmed on Thursday that PRC Coast Guard ships were directed by the its Eastern Theater Command, meaning that they are assumed to be military assets in a confrontation. Because of this, the number of assets available to the PRC navy is far, far bigger