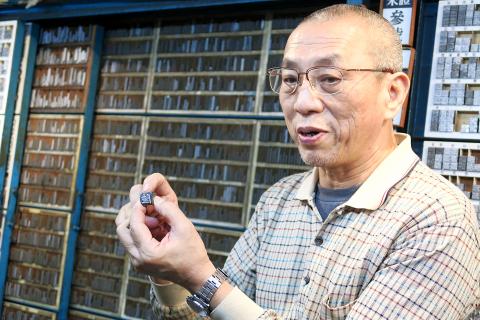

Chang Chieh-kuan (張介冠), the owner of the last Chinese character letterpress and the last lead-character moldmaker in Taiwan, has long dreamed about passing on his work so that the dying technique of which he is a master practitioner can be preserved.

However, just days before his humble shop, Rixing Type Foundry (日星鑄字行), squeezed into a small lane on Taipei’s Taiyuan Road (太原路), celebrated its 48th anniversary yesterday, 65-year-old Chang came to believe those hopes were a pipe dream and that it would be impossible to cultivate such talent.

“I will just carve as long as I can,” Chang said, as he strives to preserve the culture of Chinese letterpress printing against the passing of time and advent of new technology.

Photo: CNA

Rixing Type Foundry is possibly home to the last remaining collection of traditional Chinese movable type character molds in the world. It possesses 120,000 molds of different characters in a wide range of sizes and three different typefaces — kai ti (楷體) (regular script), song ti (宋體) and hei ti (黑體) (sans-serif black) — and has more than 10 million lead character pieces for printing or sale.

The foundry also has several molding machines that allow it to fabricate 3D lead type pieces, making it the last and only foundry of its kind in Taiwan.

However, the business might fade into history because many of its bronze molds are either partly or wholly worn.

What makes the situation even more daunting, as Chang has long feared, is that there is no way to train anyone in the skills needed to repair bronze molds for lead type.

It was in 1979 when Chang, a trained steel mechanic, started working at the lead foundry his father opened in 1969.

Training in the crafting and mending of lead type bronze molds should really start at 12 or 13, because it takes 10 to 15 years to master the skills, he said.

In addition, traditional masters remain at the peak of their abilities for about 10 years, at which point they have to rely more on experience as their eyesight deteriorates, Chang said.

“These days it is impossible to acquire apprentices aged 12 or 13. If people come here after graduating from college or university, their eyesight is already not good enough to do the job,” Chang said.

Joking that he was “forced” to enter the business, the lead type foundry master said he now often spends most of the day at his desk, mending the worn molds.

However, he said he never grows tired of the repetitive nature of tasks such as recrafting, scanning and correcting character types, which can seem extremely monotonous to an outsider. “I do not know how long the bronze molds at Rixing will last, as many of them are already badly worn,” Chang said. “I am now 65 years old. It will take another 65 years to repair them all.”

A skilled foundry master can mend a maximum of five character molds per day, he said, adding that to restore all 120,000 molds at Rixing Foundry would be extremely expensive.

Despite the time-consuming and labor intensive nature of the work, Chang told visitors to his shop that lead type imbues Chinese characters with a grandeur that digital printing cannot replicate.

It is like the difference between listening to music on vinyl or CD; it is all about the warm sentiment lead type conveys, he said.

Early this year Rixing launched a type bronze mold restoration project in the hope that an online fundraising program would help raise the funds needed to preserve its endangered bronze molds so that they can be passed on in their entirety.

“We want not only to preserve lead type, but also an era,” Chang said in a post on the project’s Web site at rixing2017.com.

“The ideal situation would be for people to express their support for the preservation of this culture through their everyday life choices,” he said.

Hon Hai Precision Industry Co (鴻海精密) yesterday said that its research institute has launched its first advanced artificial intelligence (AI) large language model (LLM) using traditional Chinese, with technology assistance from Nvidia Corp. Hon Hai, also known as Foxconn Technology Group (富士康科技集團), said the LLM, FoxBrain, is expected to improve its data analysis capabilities for smart manufacturing, and electric vehicle and smart city development. An LLM is a type of AI trained on vast amounts of text data and uses deep learning techniques, particularly neural networks, to process and generate language. They are essential for building and improving AI-powered servers. Nvidia provided assistance

DOMESTIC SUPPLY: The probe comes as Donald Trump has called for the repeal of the US$52.7 billion CHIPS and Science Act, which the US Congress passed in 2022 The Office of the US Trade Representative is to hold a hearing tomorrow into older Chinese-made “legacy” semiconductors that could heap more US tariffs on chips from China that power everyday goods from cars to washing machines to telecoms equipment. The probe, which began during former US president Joe Biden’s tenure in December last year, aims to protect US and other semiconductor producers from China’s massive state-driven buildup of domestic chip supply. A 50 percent US tariff on Chinese semiconductors began on Jan. 1. Legacy chips use older manufacturing processes introduced more than a decade ago and are often far simpler than

STILL HOPEFUL: Delayed payment of NT$5.35 billion from an Indian server client sent its earnings plunging last year, but the firm expects a gradual pickup ahead Asustek Computer Inc (華碩), the world’s No. 5 PC vendor, yesterday reported an 87 percent slump in net profit for last year, dragged by a massive overdue payment from an Indian cloud service provider. The Indian customer has delayed payment totaling NT$5.35 billion (US$162.7 million), Asustek chief financial officer Nick Wu (吳長榮) told an online earnings conference. Asustek shipped servers to India between April and June last year. The customer told Asustek that it is launching multiple fundraising projects and expected to repay the debt in the short term, Wu said. The Indian customer accounted for less than 10 percent to Asustek’s

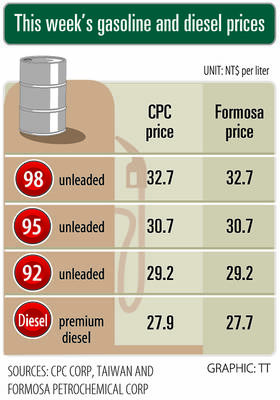

Gasoline and diesel prices this week are to decrease NT$0.5 and NT$1 per liter respectively as international crude prices continued to fall last week, CPC Corp, Taiwan (CPC, 台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. Effective today, gasoline prices at CPC and Formosa stations are to decrease to NT$29.2, NT$30.7 and NT$32.7 per liter for 92, 95 and 98-octane unleaded gasoline respectively, while premium diesel is to cost NT$27.9 per liter at CPC stations and NT$27.7 at Formosa pumps, the companies said in separate statements. Global crude oil prices dropped last week after the eight OPEC+ members said they would