Rapid wage increases are threatening China’s competitiveness, but improved productivity and other advantages mean it will continue to attract investors, analysts say.

Labor costs in China would match those of the US within four years, catching up with eurozone countries in five years and with Japan in seven, the French bank Natixis said in a study last month.

China “will soon no longer be a competitive place for production given the strong rise in the cost of production,” the bank said.

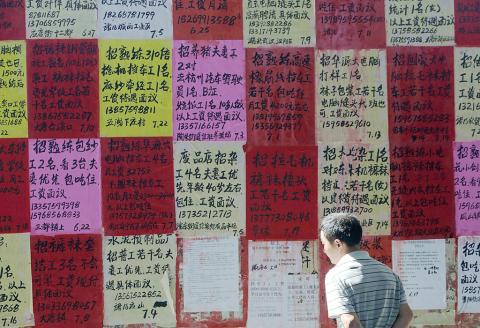

Photo: AFP

It is a view backed by the respected Boston Consulting Group (BCG), which said in a study in August last year that by around 2015 manufacturing in some parts of the US would be “just as economical as manufacturing in China.”

Examples of major manufacturers leaving China abound — BCG said US technology giant NCR has moved its manufacture of ATMs to a factory in Columbus, Georgia, that will employ 870 workers as of 2014.

Adidas announced recently that it would close its only directly owned factory in China, becoming the latest major brand to shift its manufacturing to cheaper countries, though it maintains a network of 300 Chinese contractors.

Chinese workers making athletic shoes are paid at least 2,000 yuan, or 258 euros (US$313), a month, while their Adidas colleagues in Cambodia only earn the equivalent of 107 euros, the German company said.

Underlining the trend, the salaries of Chinese urban-dwellers rose 13 percent in the first half of this year, compared with the same period last year, the government said in the middle of this month. Migrant workers, who are among the lowest-paid in the country, saw raises of 14.9 percent for an average salary of 2,200 yuan a month.

The most significant wage hikes in 2010 and last year often came following strikes at Japanese companies such as Toyota and Honda and a wave of suicides at the factories of the Taiwanese electronics giant Foxconn (富士康).

Natixis said the increases could spur manufacturers to relocate to South and Southeast Asia, where labor costs are much lower, and could also benefit countries such as Egypt and Morocco, or even European ones like Romania and Bulgaria.

However, not all economists believe China will lose its manufacturing edge, thanks in part to improvements in productivity.

“Most of the increase in wages has been offset by strong productivity growth,” said Louis Kuijs, project director at the Fung Global Institute, a research body that specializes in Asian economies.

Worker productivity has increased at a faster rate than wages in the southern Pearl River Delta, the heart of China’s vast manufacturing industry, according to 200 companies surveyed early this year by Standard Chartered Bank.

“China’s share of the world’s low-end exports has started to fall after years of rapid rises in wages, land costs and appreciation of renminbi [the currency],” said Wang Qinwei (王秦偉), a China economist at Capital Economics.

“But this has been offset by a growing market share in high-end products,” he added.

Capital Economics said in a research note published in March: “China’s export sector overall appears no less competitive now than a few years ago,” adding that “Average margins in light industry have increased over the past three years thanks to rapid productivity growth.”

China’s coastal areas offered an effective business environment that would continue to draw investors, as would lower costs in inland provinces, said Alistair Thornton, a China economist at IHS Global Insight These advantages could limit a shift in manufacturing to lower-paying countries such as Vietnam, Bangladesh, Pakistan and Indonesia.

“Guangdong and other coastal provinces have a superb advantage over most of Southeast Asia and South Asia in their efficient supply chains, strong economies of scale and reliable business environment,” Thornton said.

The US dollar was trading at NT$29.7 at 10am today on the Taipei Foreign Exchange, as the New Taiwan dollar gained NT$1.364 from the previous close last week. The NT dollar continued to rise today, after surging 3.07 percent on Friday. After opening at NT$30.91, the NT dollar gained more than NT$1 in just 15 minutes, briefly passing the NT$30 mark. Before the US Department of the Treasury's semi-annual currency report came out, expectations that the NT dollar would keep rising were already building. The NT dollar on Friday closed at NT$31.064, up by NT$0.953 — a 3.07 percent single-day gain. Today,

‘SHORT TERM’: The local currency would likely remain strong in the near term, driven by anticipated US trade pressure, capital inflows and expectations of a US Fed rate cut The US dollar is expected to fall below NT$30 in the near term, as traders anticipate increased pressure from Washington for Taiwan to allow the New Taiwan dollar to appreciate, Cathay United Bank (國泰世華銀行) chief economist Lin Chi-chao (林啟超) said. Following a sharp drop in the greenback against the NT dollar on Friday, Lin told the Central News Agency that the local currency is likely to remain strong in the short term, driven in part by market psychology surrounding anticipated US policy pressure. On Friday, the US dollar fell NT$0.953, or 3.07 percent, closing at NT$31.064 — its lowest level since Jan.

The New Taiwan dollar and Taiwanese stocks surged on signs that trade tensions between the world’s top two economies might start easing and as US tech earnings boosted the outlook of the nation’s semiconductor exports. The NT dollar strengthened as much as 3.8 percent versus the US dollar to 30.815, the biggest intraday gain since January 2011, closing at NT$31.064. The benchmark TAIEX jumped 2.73 percent to outperform the region’s equity gauges. Outlook for global trade improved after China said it is assessing possible trade talks with the US, providing a boost for the nation’s currency and shares. As the NT dollar

The Financial Supervisory Commission (FSC) yesterday met with some of the nation’s largest insurance companies as a skyrocketing New Taiwan dollar piles pressure on their hundreds of billions of dollars in US bond investments. The commission has asked some life insurance firms, among the biggest Asian holders of US debt, to discuss how the rapidly strengthening NT dollar has impacted their operations, people familiar with the matter said. The meeting took place as the NT dollar jumped as much as 5 percent yesterday, its biggest intraday gain in more than three decades. The local currency surged as exporters rushed to