Taiwan Semiconductor Manufacturing Co (TSMC, 台積電), the world’s largest contract chip maker, yesterday said it planned to spend more than NT$300 billion (US$9.34 billion) over the next few years to invest in a new chip plant in Taichung, which would create 8,000 jobs.

The company yesterday held a groundbreaking ceremony for the new semiconductor fabrication plant, or “Fab 15,” in Taichung, which was conducted by chairman and CEO Morris Chang (張忠謀).

The new facility will incorporate solar power and LED lighting with a goal of zero greenhouse gas emissions, Chang said.

PHOTO: BLOOMBERG

Fab 15 is set to create the 8,000 jobs as TSMC seeks to hire talented workers to run the fab, Chang said in a statement.

Mark Liu (劉德音), senior vice president of operations, told Bloomberg Newswires before yesterday’s ceremony that the company expects to hire up to 4,000 engineers at the site.

The factory will be TSMC’s third so-called “gigafab,” or fab with production capacity of more than 100,000 12-inch wafers per month.

It will also be the company’s second Gigafab equipped for 28-nanometer technology, the company said in the statement.

Construction of the new fab will be divided into four phases — with the first phase to start in June next year. The total investment for the fab would exceed NT$300 billion, the company said.

The fab is expected to start churning out 40nm and 28nm technology products for customers in the first quarter of 2012. More advanced process nodes will follow, it added.

The chipmaker also said yesterday that it would continue to expand capacity at its Fab 12 in Hsinchu and Fab 14 in Tainan.

“Combined capacity of Fab 12 and Fab 14 currently exceeds 200,000 12-inch wafers per month, and the total number will exceed 240,000 by the end of this year,” the statement read.

TSMC, whose clients include Qualcomm Inc and Nvidia Corp, is expanding quickly after posting record sales last quarter amid soaring global demand for computers and digital electronics.

Chang said last month the company was likely to increase capital spending again from a record high of US$4.8 billion to match the pace of a faster-than-expected recovery in electronics demand.

TSMC started increasing capital expenditures in September when it detected that a swift rebound was causing capacity constraints, bringing last year’s capital spending to US$2.7 billion in total, almost double the originally planned US$1.5 billion.

“TSMC is building out capacity now which will be yet another drag on margins over the near-term,” Bank of America Merrill Lynch said in a research note on July 12.

While the Taichung fab would focus on solar business, TSMC is also building its first LED fab in Hsinchu and expects it to be ready for mass production in the first quarter of next year, the note said.

Hon Hai Precision Industry Co (鴻海精密) yesterday said that its research institute has launched its first advanced artificial intelligence (AI) large language model (LLM) using traditional Chinese, with technology assistance from Nvidia Corp. Hon Hai, also known as Foxconn Technology Group (富士康科技集團), said the LLM, FoxBrain, is expected to improve its data analysis capabilities for smart manufacturing, and electric vehicle and smart city development. An LLM is a type of AI trained on vast amounts of text data and uses deep learning techniques, particularly neural networks, to process and generate language. They are essential for building and improving AI-powered servers. Nvidia provided assistance

GREAT SUCCESS: Republican Senator Todd Young expressed surprise at Trump’s comments and said he expects the administration to keep the program running US lawmakers who helped secure billions of dollars in subsidies for domestic semiconductor manufacturing rejected US President Donald Trump’s call to revoke the 2022 CHIPS and Science Act, signaling that any repeal effort in the US Congress would fall short. US Senate Minority Leader Chuck Schumer, who negotiated the law, on Wednesday said that Trump’s demand would fail, while a top Republican proponent, US Senator Todd Young, expressed surprise at the president’s comments and said he expects the administration to keep the program running. The CHIPS Act is “essential for America leading the world in tech, leading the world in AI [artificial

DOMESTIC SUPPLY: The probe comes as Donald Trump has called for the repeal of the US$52.7 billion CHIPS and Science Act, which the US Congress passed in 2022 The Office of the US Trade Representative is to hold a hearing tomorrow into older Chinese-made “legacy” semiconductors that could heap more US tariffs on chips from China that power everyday goods from cars to washing machines to telecoms equipment. The probe, which began during former US president Joe Biden’s tenure in December last year, aims to protect US and other semiconductor producers from China’s massive state-driven buildup of domestic chip supply. A 50 percent US tariff on Chinese semiconductors began on Jan. 1. Legacy chips use older manufacturing processes introduced more than a decade ago and are often far simpler than

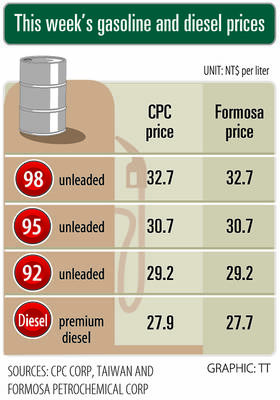

Gasoline and diesel prices this week are to decrease NT$0.5 and NT$1 per liter respectively as international crude prices continued to fall last week, CPC Corp, Taiwan (CPC, 台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. Effective today, gasoline prices at CPC and Formosa stations are to decrease to NT$29.2, NT$30.7 and NT$32.7 per liter for 92, 95 and 98-octane unleaded gasoline respectively, while premium diesel is to cost NT$27.9 per liter at CPC stations and NT$27.7 at Formosa pumps, the companies said in separate statements. Global crude oil prices dropped last week after the eight OPEC+ members said they would