Taiwan’s young solar power industry is gearing up for expansion, but it should become self-sufficient in procurement if it wants to increase its global competitiveness, industry experts said at an exhibition yesterday.

Tsai Hsin-yuan (蔡新源), CEO of the Industrial Technology Research Institute’s (ITRI, 工業技術研究院) southern branch, said that Taiwan’s high-tech sectors previously sought production capacity expansion before self-sufficiency in equipment procurement, which was often the case in the semiconductor and flat-panel display sectors.

“However, for the solar power sector, if we aim to achieve higher international competitiveness, we have to reverse this mindset and put equipment self-sufficiency before capacity expansion,” Tsai said.

According to ITRI, Taiwan’s solar power industry generated an output value of NT$53.5 billion (US$1.74 billion) last year. The total value is expected to rise to NT$90 billion this year before hitting NT$400 billion in 2015.

Tsai was speaking at the first Solar Optoelectronic Equipment Forum & Exposition, which was held in Tainan County yesterday.

About 400 representatives of Taiwan’s solar power industry participated in the exhibition, an organizer said.

Organized by the ITRI, the Taiwan Photovoltaic Industry Association and the Taiwan Optoelectronic and Semiconductors Equipment Association, the meeting focused on future trends in the industry while reviewing current achievements in research and development.

One trend is self-sufficiency in manufacturing equipment procurement — buying equipment from domestic companies instead of foreign sources.

Huang Ying-chien (黃英堅), a section chief at the economic affairs ministry’s Industrial Development Bureau, told the forum that only a small part of the equipment used by the local photovoltaic industry is domestically produced.

However, the bureau hoped to raise that ratio to 80 percent by 2013, Huang said.

“This goal may look difficult to achieve at present, but it will become reachable if industry-academia cooperation can be strengthened,” Huang said.

Meanwhile, R&D in advanced, efficient equipment is also essential, according to industry experts.

Lan Chung-wen (藍崇文), director-general of ITRI’s Photovoltaics Technology Center, said that the institute was working on refining the manufacturing process of silicon thin film and print CIGS (copper indium gallium selenide) solar cells.

“The production output capacity of mainstay silicon crystal-based cells relies heavily on sufficient raw material supply, which has become increasingly strained in recent years,” Lan said. “Thin film and print CIGS, however, rely more on advanced equipment and technology.”

“So far, no country in the world has successfully applied these two sets of production techniques to mass production, which means that if Taiwan can take the lead in these areas, we may gain a valuable edge over international competitors,” Lan said.

Hon Hai Precision Industry Co (鴻海精密) yesterday said that its research institute has launched its first advanced artificial intelligence (AI) large language model (LLM) using traditional Chinese, with technology assistance from Nvidia Corp. Hon Hai, also known as Foxconn Technology Group (富士康科技集團), said the LLM, FoxBrain, is expected to improve its data analysis capabilities for smart manufacturing, and electric vehicle and smart city development. An LLM is a type of AI trained on vast amounts of text data and uses deep learning techniques, particularly neural networks, to process and generate language. They are essential for building and improving AI-powered servers. Nvidia provided assistance

GREAT SUCCESS: Republican Senator Todd Young expressed surprise at Trump’s comments and said he expects the administration to keep the program running US lawmakers who helped secure billions of dollars in subsidies for domestic semiconductor manufacturing rejected US President Donald Trump’s call to revoke the 2022 CHIPS and Science Act, signaling that any repeal effort in the US Congress would fall short. US Senate Minority Leader Chuck Schumer, who negotiated the law, on Wednesday said that Trump’s demand would fail, while a top Republican proponent, US Senator Todd Young, expressed surprise at the president’s comments and said he expects the administration to keep the program running. The CHIPS Act is “essential for America leading the world in tech, leading the world in AI [artificial

DOMESTIC SUPPLY: The probe comes as Donald Trump has called for the repeal of the US$52.7 billion CHIPS and Science Act, which the US Congress passed in 2022 The Office of the US Trade Representative is to hold a hearing tomorrow into older Chinese-made “legacy” semiconductors that could heap more US tariffs on chips from China that power everyday goods from cars to washing machines to telecoms equipment. The probe, which began during former US president Joe Biden’s tenure in December last year, aims to protect US and other semiconductor producers from China’s massive state-driven buildup of domestic chip supply. A 50 percent US tariff on Chinese semiconductors began on Jan. 1. Legacy chips use older manufacturing processes introduced more than a decade ago and are often far simpler than

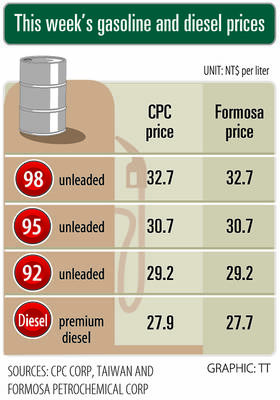

Gasoline and diesel prices this week are to decrease NT$0.5 and NT$1 per liter respectively as international crude prices continued to fall last week, CPC Corp, Taiwan (CPC, 台灣中油) and Formosa Petrochemical Corp (台塑石化) said yesterday. Effective today, gasoline prices at CPC and Formosa stations are to decrease to NT$29.2, NT$30.7 and NT$32.7 per liter for 92, 95 and 98-octane unleaded gasoline respectively, while premium diesel is to cost NT$27.9 per liter at CPC stations and NT$27.7 at Formosa pumps, the companies said in separate statements. Global crude oil prices dropped last week after the eight OPEC+ members said they would