Taiwan is in a race with international designers to create alternatives to the traditional keyboard that aim to reduce injuries and increase mobility. Designs of the future may be anything from flexible keyboards you can roll up, to foldable models, to devices you can wear on your hand like a glove.

Taiwanese are well positioned to make the next generation of keyboards.

Technology matchmaker Phil Singleton of BridgeTech-Asia works to marry foreign designers and local manufacturers.

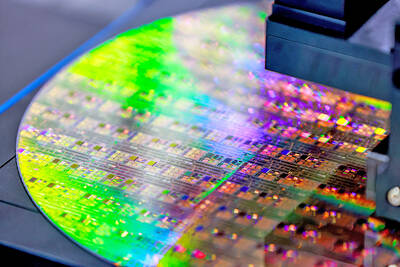

PHOTO: SAMSUNG ADVANCED INSTITUTE OF TECHNOLOGY

"Innovations are coming from all over the world, but the mass manufacturing is based here," he told the Taipei Times yesterday. "The Taiwanese have long-standing relationships with their big OEM partners and increasingly need to present them with innovations."

Singleton is currently seeking Taiwanese partners for the US-developed FrogPad, a keyboard that is just a third of the size of the traditional keyboard. The FrogPad features 15 standard-size keys in a central pad that covers 80 percent of the most commonly used letters in English, Singleton said.

By pressing a key on the lower section of the pad, users can type the less frequently used letters and characters. The device has distinct advantages over current mini designs that have shrunk the size of the keys, making them difficult to use, Singleton said.

The standard "Qwerty" keyboard -- named for the first six letter keys -- was developed in 1868 by Christopher Sholes, inventor of the typewriter. Sholes separated the most commonly used keys to prevent them from jamming. When electronic and computer keyboards were developed, they inherited the Qwerty layout.

But one ergonomics professor said the keyboard lay-out was not the problem.

"The issue with keyboards is not the layout but the upward sloping angle of the keys that causes the wrists to bend upwards, putting pressure on the carpal tunnel, and this is the primary risk factor for injury," Alan Hedge, director of the Human Factors and Ergonomics Laboratory at Cornell University said in an e-mail. "So the flatter the keyboard the better."

This is good news for UK start-up ElekSen Ltd which has developed a super-thin fabric keyboard that can be used with personal digital assistants (PDAs), smart phones and tablet computers. Representatives from the company are in town this week to find Taiwanese partners, but were unavailable for comment yesterday.

A local company that produces a flat rubber roll-up keyboard is Ezkey Corp (

Ezkey also manufactures three-section fold-out keyboards for PDAs that unfold from pocket-size into a full-size keyboard. The firm also makes split keyboards -- where the keys are separated into two halves -- that increase the distance between the two hands when typing.

Ergonomics professors recommend this kind of design, saying it reduces the strain on the hands.

Hedge also recommends placing the keyboard at lap height so that the elbow is at an angle greater than 90 degrees and tilting the keyboard away so that the wrists are not forced to bend upwards.

One option may be to dump the keyboard altogether. The Virtual Keyboard from Israel's VKB Ltd is an infrared projection of a keyboard that can be displayed on any flat surface. The projector unit is also a sensor that detects the typist's finger movements and translates them into the appropriate character or keystroke on a computer screen.

Last year South Korea's Samsung Advanced Institute of Technology unveiled a wearable keyboard which fits on one hand. The space-age device looks like high-tech brass knuckles with two wristwatch-like bands. The component parts detect the movements of the user's fingers and hand and translate them into keystrokes on a "soft" keyboard on the screen of a computer.

Taiwan’s foreign exchange reserves hit a record high at the end of last month, surpassing the US$600 billion mark for the first time, the central bank said yesterday. Last month, the country’s foreign exchange reserves rose US$5.51 billion from a month earlier to reach US$602.94 billion due to an increase in returns from the central bank’s portfolio management, the movement of other foreign currencies in the portfolio against the US dollar and the bank’s efforts to smooth the volatility of the New Taiwan dollar. Department of Foreign Exchange Director-General Eugene Tsai (蔡炯民)said a rate cut cycle launched by the US Federal Reserve

The US government on Wednesday sanctioned more than two dozen companies in China, Turkey and the United Arab Emirates, including offshoots of a US chip firm, accusing the businesses of providing illicit support to Iran’s military or proxies. The US Department of Commerce included two subsidiaries of US-based chip distributor Arrow Electronics Inc (艾睿電子) on its so-called entity list published on the federal register for facilitating purchases by Iran’s proxies of US tech. Arrow spokesman John Hourigan said that the subsidiaries have been operating in full compliance with US export control regulations and his company is discussing with the US Bureau of

Businesses across the global semiconductor supply chain are bracing themselves for disruptions from an escalating trade war, after China imposed curbs on rare earth mineral exports and the US responded with additional tariffs and restrictions on software sales to the Asian nation. China’s restrictions, the most targeted move yet to limit supplies of rare earth materials, represent the first major attempt by Beijing to exercise long-arm jurisdiction over foreign companies to target the semiconductor industry, threatening to stall the chips powering the artificial intelligence (AI) boom. They prompted US President Donald Trump on Friday to announce that he would impose an additional

Pegatron Corp (和碩), a key assembler of Apple Inc’s iPhones, on Thursday reported a 12.3 percent year-on-year decline in revenue for last quarter to NT$257.86 billion (US$8.44 billion), but it expects revenue to improve in the second half on traditional holiday demand. The fourth quarter is usually the peak season for its communications products, a company official said on condition of anonymity. As Apple released its new iPhone 17 series early last month, sales in the communications segment rose sequentially last month, the official said. Shipments to Apple have been stable and in line with earlier expectations, they said. Pegatron shipped 2.4 million notebook